Introduction

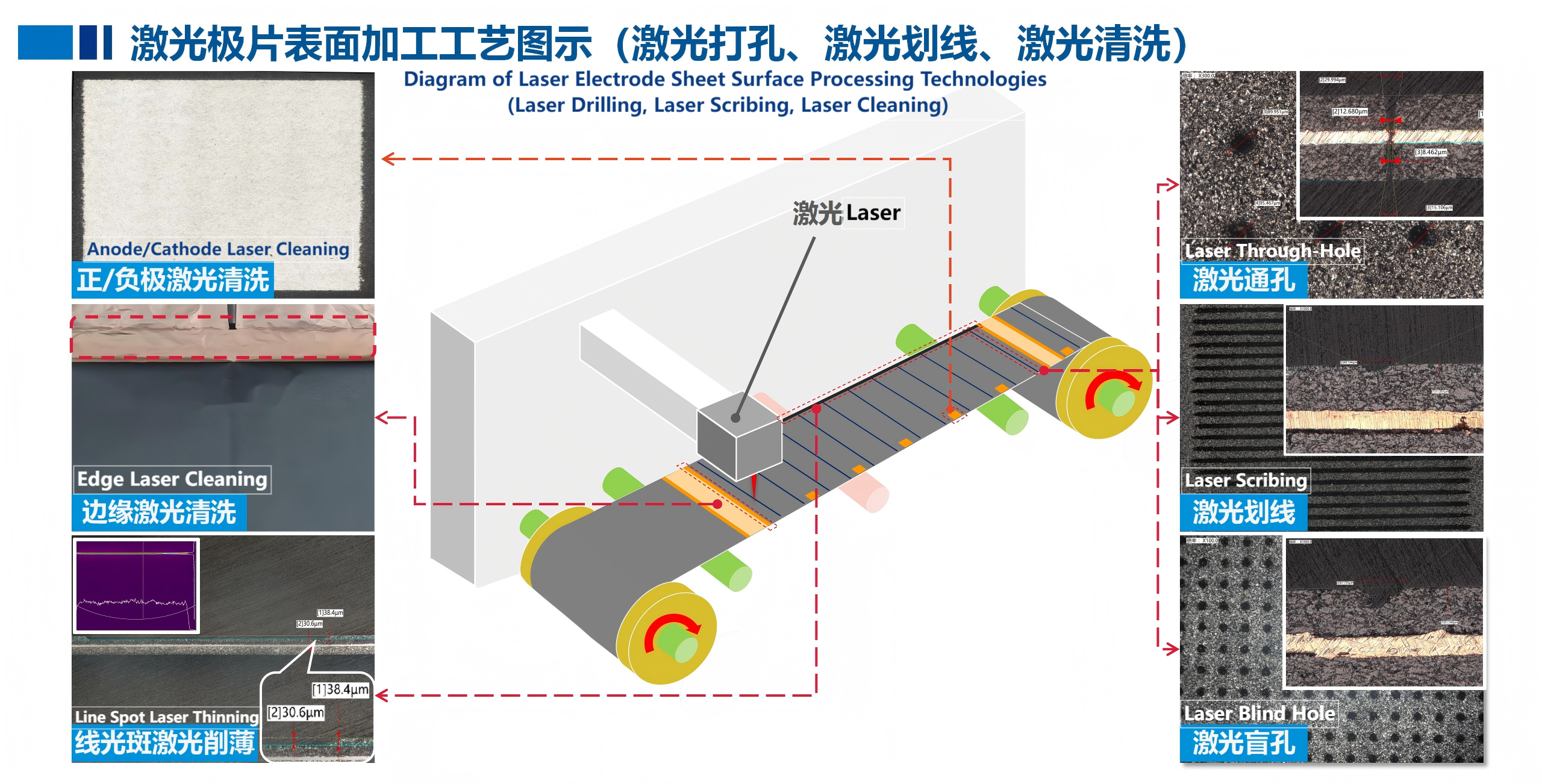

The UW laser surface processing (etching) machine is specifically designed for the surface treatment of positive and negative electrode sheets in lithium battery production. Its core mission is to significantly enhance the overall performance of batteries through precision laser processing technology. The core principle of the equipment lies in using a high-precision laser beam to scribe lines on the coating area of wide-format battery electrode sheets, which increases the surface area, expands the contact area with the electrolyte, and improves the efficiency of lithium ion intercalation and deintercalation, thereby optimizing the charge-discharge performance of battery cells.

Core Functions and Design

Efficient Double-Sided Processing: The equipment adopts an innovative double-side platen support structure design. It enables etching of both sides of electrode sheets in a single loading and unloading cycle, greatly simplifying the process and saving space.

Advanced Detection and Dust Removal: Equipped with a multi-stage high-efficiency dust removal and dust detection system to ensure a clean processing environment. Integrated with online 3D depth detection and 2D spacing dimension detection functions, it monitors processing quality in real-time and guarantees consistency.

Excellent Compatibility: Compatible with various processes such as continuous and discontinuous coating. Supports three core processing modes—horizontal scribing, horizontal-vertical alternating scribing, and drilling (through holes/blind holes)—to meet different battery process requirements.

High-Speed and Stable Processing: Equipped with UW Laser's self-developed multi-station laser flying processing galvanometer control system. Combined with precision cam motion algorithms and real-time tension control technology, it achieves industry-leading etching speed (up to 120 meters per minute for scribing) and extremely high operational stability.

Equipment Advantages and Features

The advantages of the UW Laser Surface Treatment (Etching) Machine are reflected not only in technical parameters but also directly translated into tangible benefits for customers:

Efficiency Leap & Capacity Doubling

Combined with the self-developed "multi-station laser flying processing galvanometer control system" and mature laser processes, production efficiency is increased by 50%.

The "rapid changeover" function enables quick adaptation to different production process requirements, reducing downtime.

Superior Yield & Cost Savings

The equipment has undergone rigorous stability optimization, achieving a production yield of up to 99.5%. High yield directly saves approximately 10% in raw material costs, reducing waste and rework.

Performance Enhancement & Product Leadership

Through electrode sheet etching, the root cause of lithium plating in lithium batteries is addressed. It improves battery safety and comprehensively enhances battery performance by about 10%.

Space Optimization & Flexible Customization

The design of completing double-sided processing in a single loading/unloading cycle, along with a compact overall structure, significantly saves equipment floor space and improves customer workshop utilization. Modular design allows configuration according to customers' production line requirements.

End

The UW Laser Surface Processing (Etching) Machine is the crystallization of integrating the pain points of lithium-ion battery manufacturing with cutting-edge laser technology. It is not only a processing equipment, but also a comprehensive solution to enhance battery performance, ensure production safety, optimize manufacturing costs and improve plant utilization. Its core advantages of high efficiency, high yield, high stability and high compatibility, as well as independently developed core technologies (such as multi-station laser flight control system, tension control technology and deformation compensation technology), ensure the equipment's leading position in the industry.

In the future, UW Laser will continue to increase investment in technological R&D, launch more innovative equipment, and help the lithium-ion battery industry stride forward into the era of high performance.