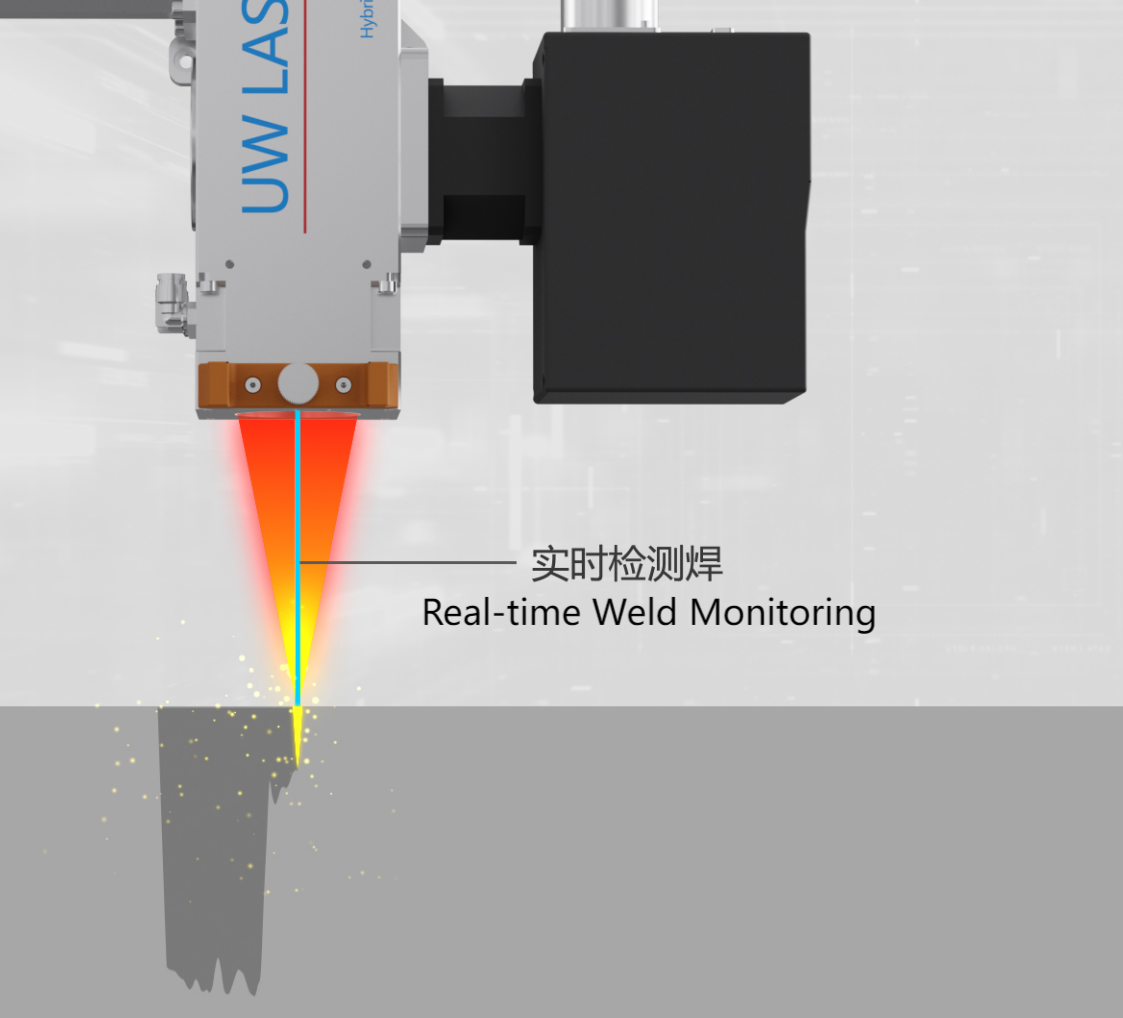

Amid the rapid growth of new energy vehicles, 3C electronics and energy storage equipment, laser welding faces unprecedented precision challenges. Traditional quality inspection is like blind checks on a high-speed train: destructive sampling misses full-cycle production, X-ray/ultrasonic offline testing is inefficient, and lack of weld depth data keeps batch defect rates high. UW Laser’s self-developed "RWD Real-Time Weld Depth Detection System" applies FD-OCT to industry, ushering welding quality inspection into a new era of full-process data-driven management.

01 Solid R&D Efforts to Address Core Welding Pain Points in the Industry

As the requirements for welding precision in fields such as new energy vehicles and 3C electronics continue to rise, traditional inspection methods have exposed systemic flaws:

Lack of Full-process Control

Production lines rely on first-piece sampling inspection and destructive metallographic testing (with a coverage rate of <5%), which fail to monitor the full-time dynamic changes of welding depth.

Failure in Real-time Response

Offline inspections such as X-ray and ultrasonic testing take 30 minutes per piece, which are completely ineffective in dealing with microsecond-level molten pool fluctuations during high-speed welding (≥10 m/min).

Penetration Depth Data Vacuum

Traditional methods can only observe surface morphology, and the lack of key penetration depth data leads to a batch defect rate of over 15%, resulting in a sharp increase in quality costs.

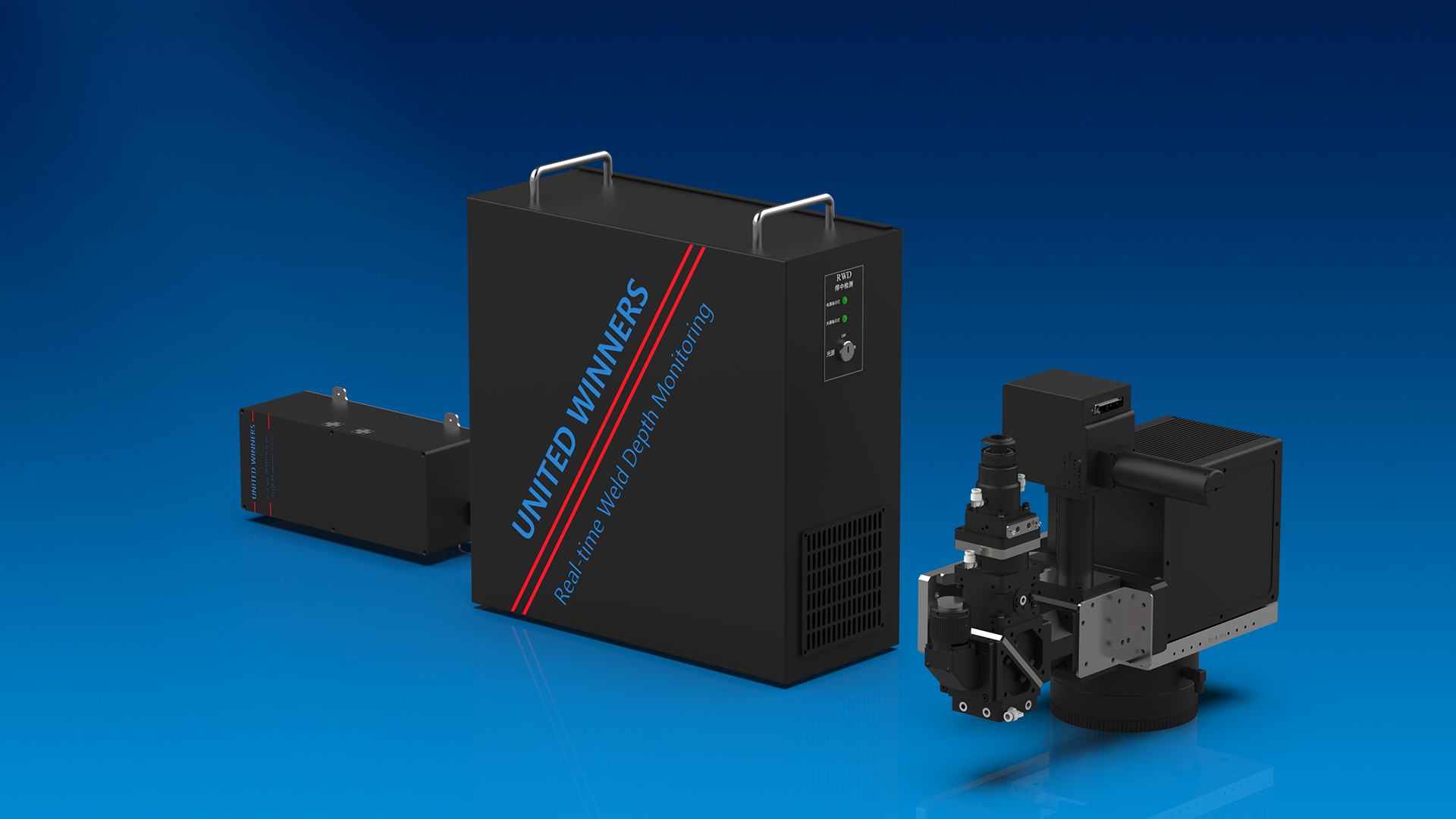

UW Laser assembled a 32-expert R&D team (covering optics, mechanics, electrical engineering and software). After 4 years and over 10 million yuan of investment, it achieved three core technological breakthroughs and independently developed the "RWD Real-time Weld Penetration Detection System" — enabling industrial application of FD-OCT. Designed for full-process quality monitoring of deep penetration welding (welding with keyhole formation), it safeguards weld quality throughout.

With a complete technology chain built via 100% self-developed optical paths, algorithms and software, the "RWD System" delivers micron-level detection performance. It turns "real-time 100% weld penetration inspection" from a lab concept into a mass-production tool. Dozens of systems have been delivered, with repeat orders from leading lithium battery clients, making it a "standard configuration" for process upgrades in the power battery and precision electronics sectors.

02 Technological Breakthroughs: Redefining Industry Standards

The RWD System uses Frequency-Domain Optical Coherence Tomography (FD-OCT), which measures weld depth with high precision via a Michelson interferometer. When a keyhole (recessed structure) forms during welding, the sample light’s optical path length increases. By analyzing such changes (e.g., from 5000μm (unwelded) to 5500μm (welded), indicating a 500μm keyhole depth), the system calculates weld depth in real time with micron-level accuracy—like using light waves as a high-precision "ruler" for dynamic measurement. This solves the industry blind spot where traditional methods cannot obtain real-time metallographic penetration.

Powered by GPU-accelerated parallel computing for real-time interference signal processing, the RWD System has a sampling rate of up to 250,000 points/second to track molten pool fluctuations accurately. It offers selectable detection resolutions (20μm/10μm/5μm): for thick materials (≥1mm), penetration accuracy is <100μm (or <10% of total penetration); for thin materials (200-400μm), <30μm. With strong anti-interference capability (>80dB sensitivity) to withstand intense welding light, it ensures near-zero missed detection in high-speed production. Validated in hundreds of thousands of tests and operating stably for over a year, its false judgment rate is below industry standards, providing full-time 100% penetration inspection for power batteries, precision electronics, etc.

What is more noteworthy is that its intelligent optical path dynamic calibration system enables automatic calibration of detection light and welding light via high-precision signal acquisition and peak positioning (error <10μm). This ensures accurate coaxial alignment of the two beams and effectively resolves optical path deviation caused by mechanical displacement. The system has three core advantages:

High Stability

Eliminates detection drift for reliable 365-day continuous production

Fully Auto Calibration

Completes calibration within 30 seconds after startup, vibration or plugging/unplugging, no manual intervention needed

Intelligent Compensation

Dynamically adjusts the optical path to adapt to external interference and ensure detection consistency

In addition, the RWD system innovatively develops 5 weld depth tracking algorithm combinations, which intelligently filter spatter noise and multiple reflection interference signals. It dynamically adapts to diverse welding scenarios (galvanometer scanners, laser heads, wobble heads) for accurate weld depth detection in high-speed production. Meanwhile, it integrates four intelligent calibration systems for stable operation under harsh conditions:

Dynamic Chromatic Aberration Compensation

Real-time full-frame/partition calibration for complex welding fields of view

Defocus Amount Sync Compensation

Boosts multi-station signal stability by 300%

Intelligent Beam Alignment

Keyhole 3D scanning + pulse point positioning (error <10μm)

Environmental Noise Suppression

Automatically corrects long-term system drift

The RWD system supports quick changeover of 20 detection configurations (done via file switching) and has a custom quality assessment (QA) system. It flexibly adapts to process iterations, enabling full-coverage detection from simple flat surfaces to complex curved ones.

In addition, the system supports three-way interaction between local storage, MES systems and databases for weld spot-level quality traceability. Key mechanisms are optimized through multi-physics simulation (motion interference/vibration mode/fatigue analysis), extending critical component life by 30%. Combined with daily automatic calibration and support from a professional welding team, it significantly cuts maintenance costs and ensures continuous reliability amid vibration, temperature fluctuations and other conditions.

END

UW Laser's "RWD Real-time Weld Depth Detection System" builds a "detection-feedback-optimization" real-time control loop in laser welding, relying on micron-level full penetration inspection, millisecond-response dynamic control and adaptive intelligent algorithm core. It fully ends the era of "sampling inspection blind spots" in welding quality inspection.

In the future, UW Laser will use its real-time, data-driven and highly reliable technical core to continuously advance laser welding toward the zero-defect era.