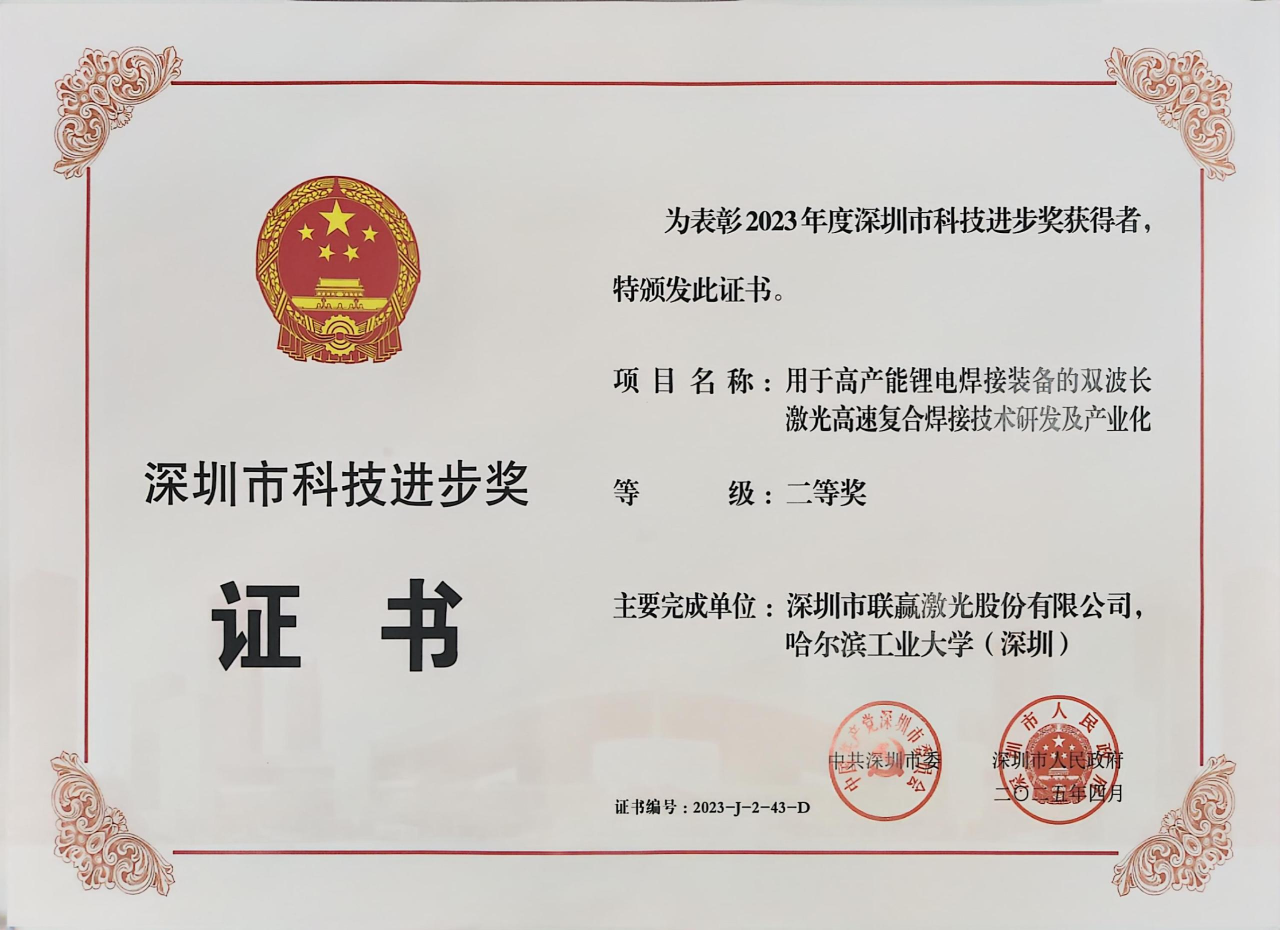

Recently, the honorary certificates for the "2023 Shenzhen Science and Technology Progress Award" were officially issued. After strict selection and fair evaluation by the relevant departments of the Shenzhen Municipal Party Committee, the project "R&D and Industrialization of Dual-Wavelength Laser High-Speed Hybrid Welding Technology for High-Capacity Lithium Battery Welding Equipment", jointly launched by United Winners Laser Co., Ltd. and Harbin Institute of Technology (Shenzhen), won the Second Prize of the 2023 "Shenzhen Science and Technology Progress Award" by virtue of its significant technological innovation and outstanding application value.

The Shenzhen Science and Technology Progress Award is a municipal-level science and technology award established by the Shenzhen Municipal Government. It aims to recognize individuals and organizations that have accomplished, applied, and promoted innovative scientific and technological achievements, as well as made outstanding contributions to advancing scientific and technological progress and social development. It represents the highest recognition from the Shenzhen Municipal Government for projects with significant technological breakthroughs and industrialization value.

UW Laser's award-winning project, "R&D and Industrialization of Dual-Wavelength Laser High-Speed Hybrid Welding Technology for High-Capacity Lithium Battery Welding Equipment", adopts the independently developed dual-wavelength laser high-speed hybrid welding technology of our company (which won the "China Industrial Laser Innovation Contribution Award" in 2018). Compared with the traditional single-wavelength laser welding technology commonly used in the industry, which is prone to spatter and porosity defects, this innovative technology has achieved significant breakthroughs:

Leading Technology

It pioneered the integration of fiber laser and semiconductor laser in China for welding key power battery components (top covers, sealing nails, poles, adapter plates). Its innovative wavelength beam combining and multi-module integrated control replace traditional single-wavelength solutions, enabling high-speed (up to 300mm/s) and high-quality welding of aluminum/copper workpieces with more stable processes, less spatter and fewer post-welding defects.

Superior Performance

Precise control ensures stable molten pools and ultra-low spatter. High-power-density fiber laser forms small, deep keyholes for effective welding; larger-spot, high-absorption semiconductor laser expands keyhole openings, allowing high-pressure gas to escape and minimizing spatter. Even occasional spatter is only 20-30μm, far smaller than conventional hundred-micron-level spatter.

Higher Efficiency

By combining blue and near-infrared lasers, copper welding laser utilization rises from <5% (single-wavelength) to >30%, and quickly reaches full keyhole absorption for optimal efficiency, meeting international advanced standards.

Broad Application Potential

It solves the industry challenge of high-speed, high-quality welding of aluminum/copper. Its high speed, stability and low spatter make it a foundational technology for ensuring stability, consistency and safety in large-scale power battery production.

The dual-wavelength laser high-speed hybrid welding technology marks a major boost to China's welding manufacturing capabilities. Its abovementioned advantages are critical to ensuring stability, consistency and safety in mass power battery production. Compared with traditional processes, it cuts material waste and labor costs, produces no harmful fumes (meeting environmental standards), and will strongly drive technological upgrading in industrial chains like automotive power batteries, 3C electronics, photovoltaics and high-end equipment manufacturing.

The company has long independently developed laser welding heads and other peripheral optical systems. Its laser welding heads cover 5W to 8000W in power and 266nm (UV) to 2000nm in wavelength. It has also developed China's first multi-wavelength coaxial hybrid welding head, supporting up to 8000W single-wavelength power and on a par with international leaders.