Recently, the 2024 New Energy Intelligent Manufacturing Summit (The 3rd Edition), themed "Leading New Energy with Intelligence, Creating the Future with Lean Production," organized by Gaogong Robot and the Gaogong Robotics Industry Research Institute (GGII), kicked off in Changzhou. The list of the Top 30 in Intelligent Manufacturing for the New Energy Industry was officially announced.

UW Laser has stood out in the field of intelligent manufacturing for lithium battery equipment, thanks to its outstanding innovation capabilities and research strength. The company has been named to the 2024 Top 30 in Intelligent Manufacturing for the New Energy Industry and has been awarded the title of "2024 Benchmark Solution in New Energy Intelligent Manufacturing."

This event brought together numerous renowned companies, resulting in fierce competition. The awards were determined based on a comprehensive evaluation of each company's product innovation, technological level, delivery verification, growth rate, channel layout, and industry reputation. The event showcased advanced technologies, intelligent products, and solutions in China's new energy sector, showing the development trends in China's advanced manufacturing industry.

As a pioneer in lithium battery laser welding technology, UW Laser has been deeply engaged in the lithium battery manufacturing industry for over 10 years, offering complete line solutions from cells to module PACK assembly. Its equipment excels in efficiency, leveraging automation and intelligence to drive a significant leap in new productivity for the automotive manufacturing sector.

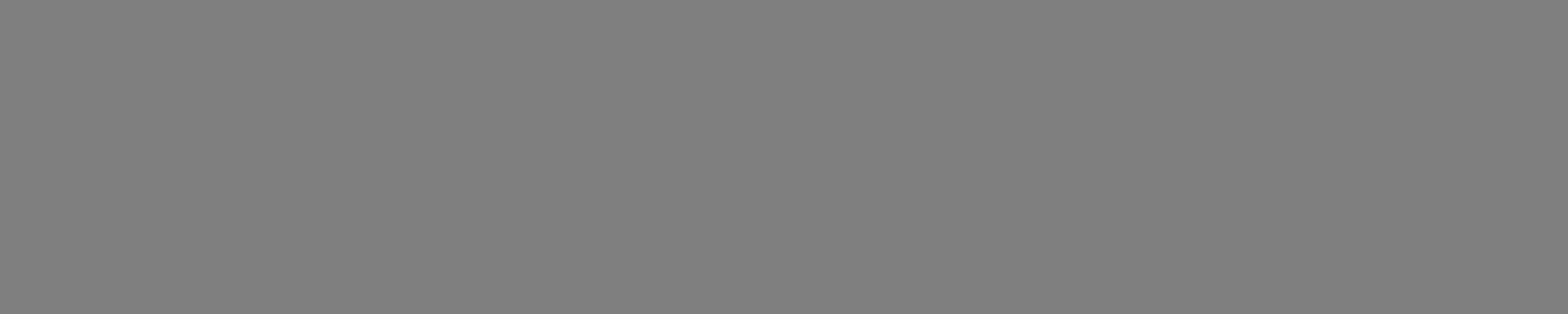

In the mid-stage of lithium battery manufacturing, the cell assembly process requires highly for equipment precision, efficiency, and stability. We launched the 30PPM prismatic cell high-speed assembly line, the 24PPM blade battery fully automated assembly line, and the 300PPM cylindrical cell assembly line. These innovations respond rapidly to high production demands and lead the way in cutting-edge intelligent manufacturing.

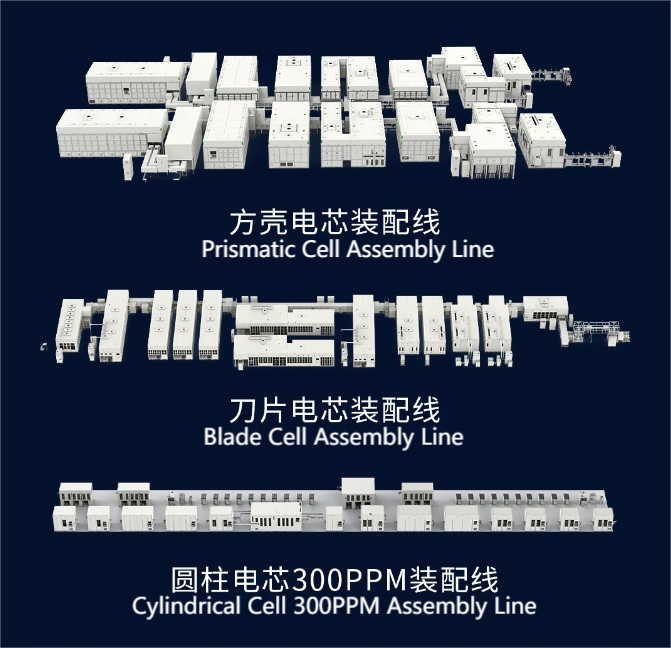

In the module PACK stage of lithium battery manufacturing, UW Laser’s self-developed prismatic power module PACK line, soft-pack module PACK line, cylindrical module PACK line, and CCS automatic assembly line significantly enhance production efficiency and quality standards for industry clients, continuously empowering intelligent manufacturing in the lithium battery sector.

UW Laser's recognition on this honor roll, ranking among the top 30, not only highlights its leading position in the intelligent manufacturing of complete line equipment for new energy power batteries but also represents high recognition of its years of dedication to the lithium battery industry and its contribution to the development of the new energy sector.