In the rapidly developing new energy era, technological innovation has become the key to enterprises' sustainable development. Leveraging its deep technical expertise and precise market demand analysis, UW Laser has developed the cylindrical cell assembly line and module Pack line characterized by high efficiency, reliability, and stability. These production lines not only meet the needs of different customers but have also gained widespread recognition and cooperation opportunities in both domestic and international markets.

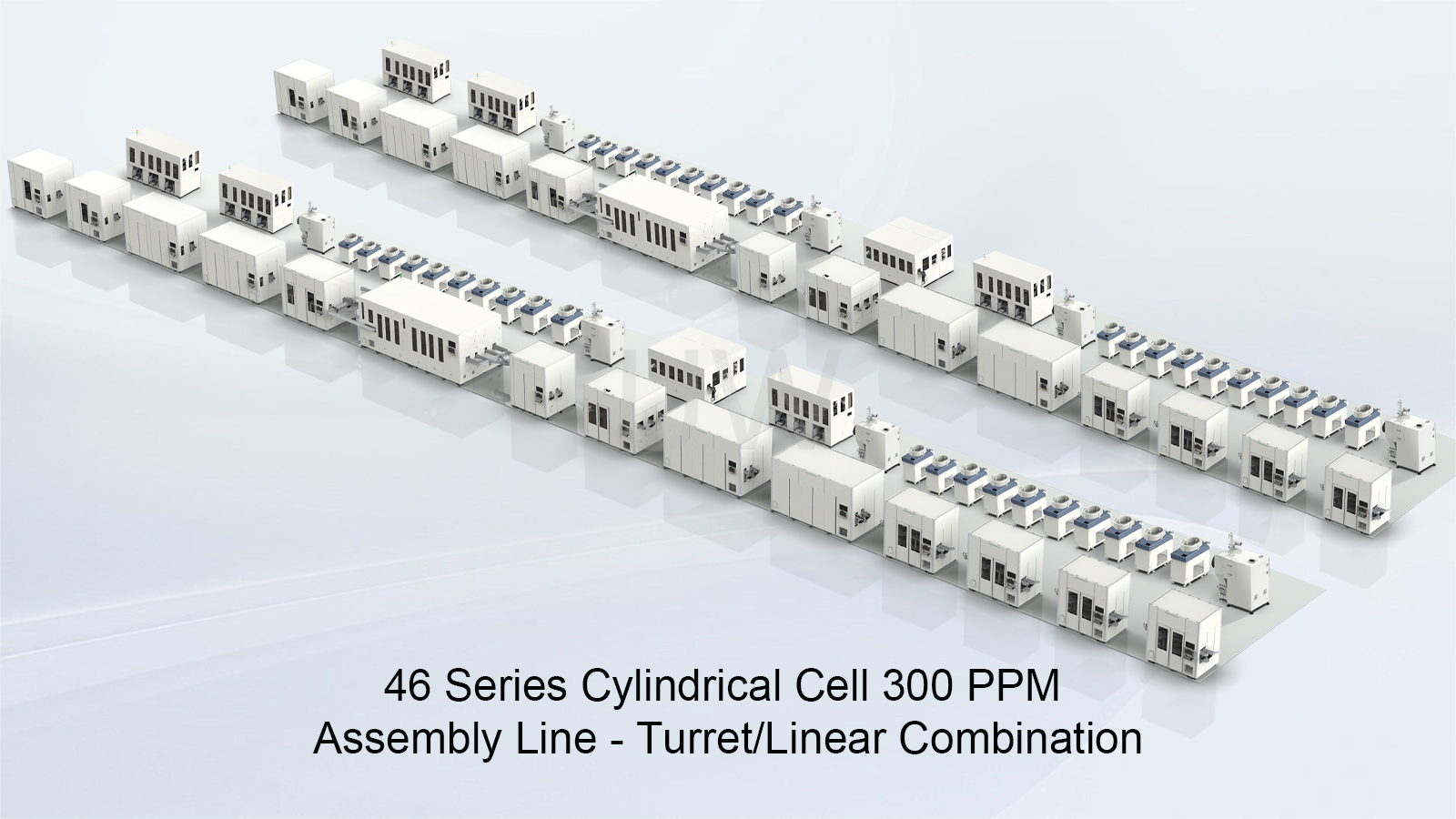

46 Series Cylindrical Cells

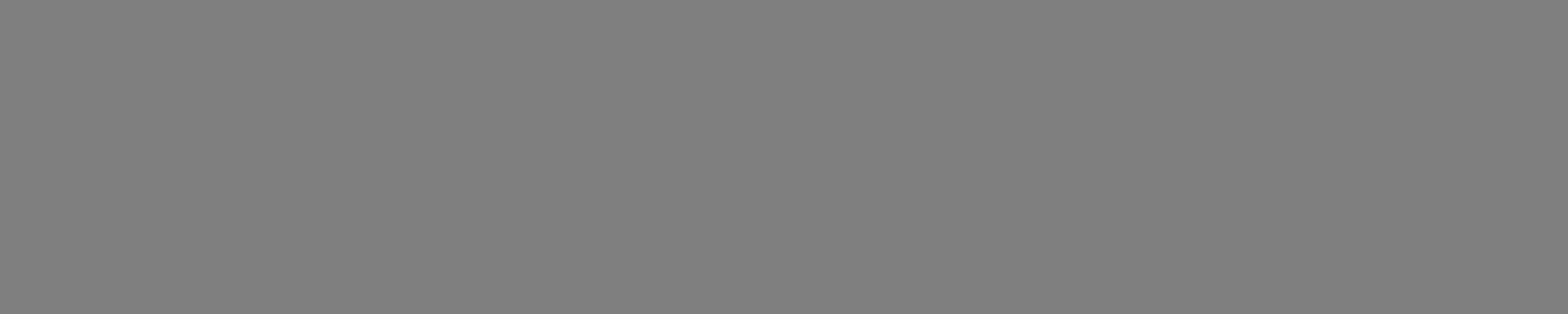

300 PPM Assembly Line - Turret/Linear Combination

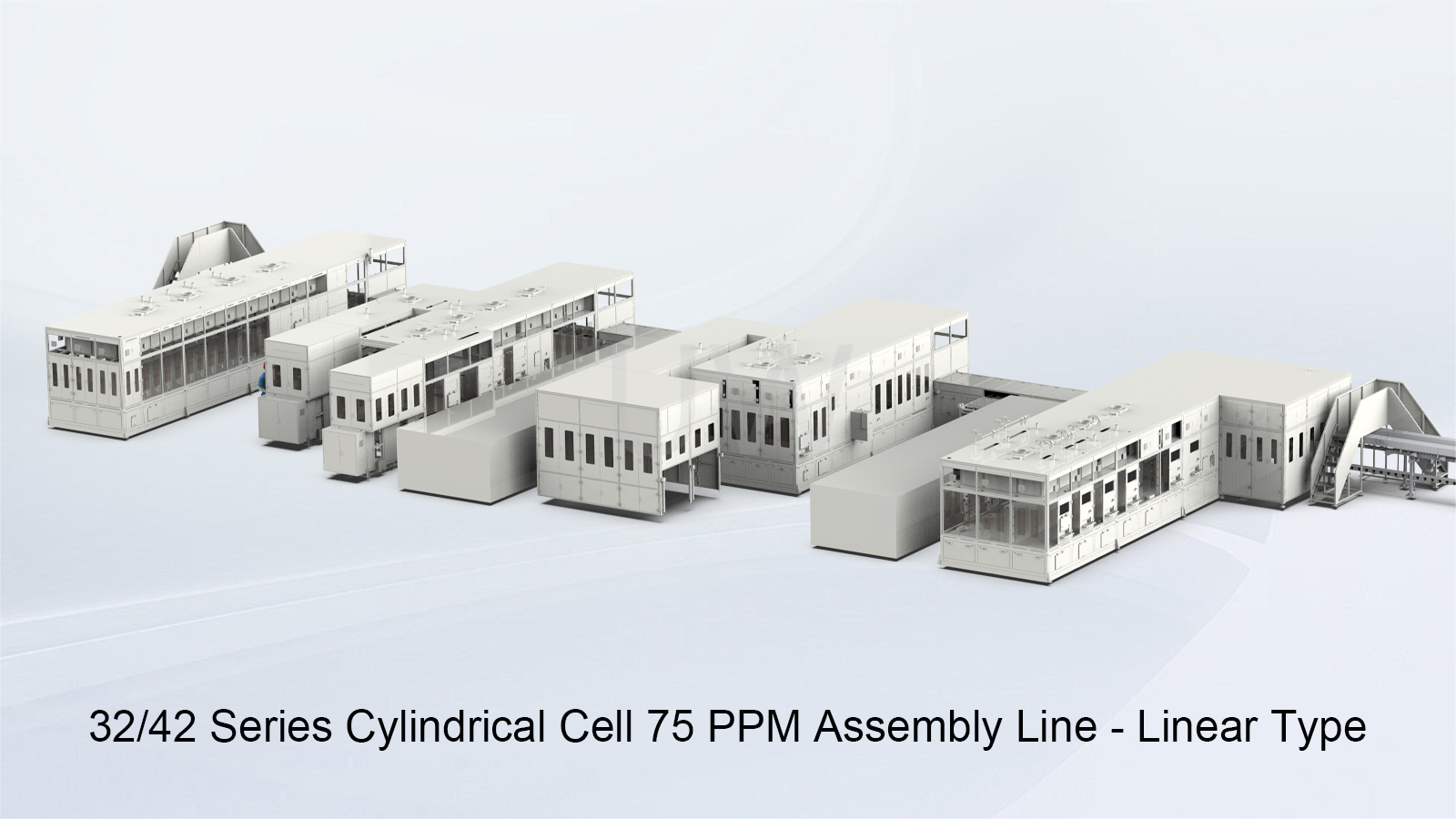

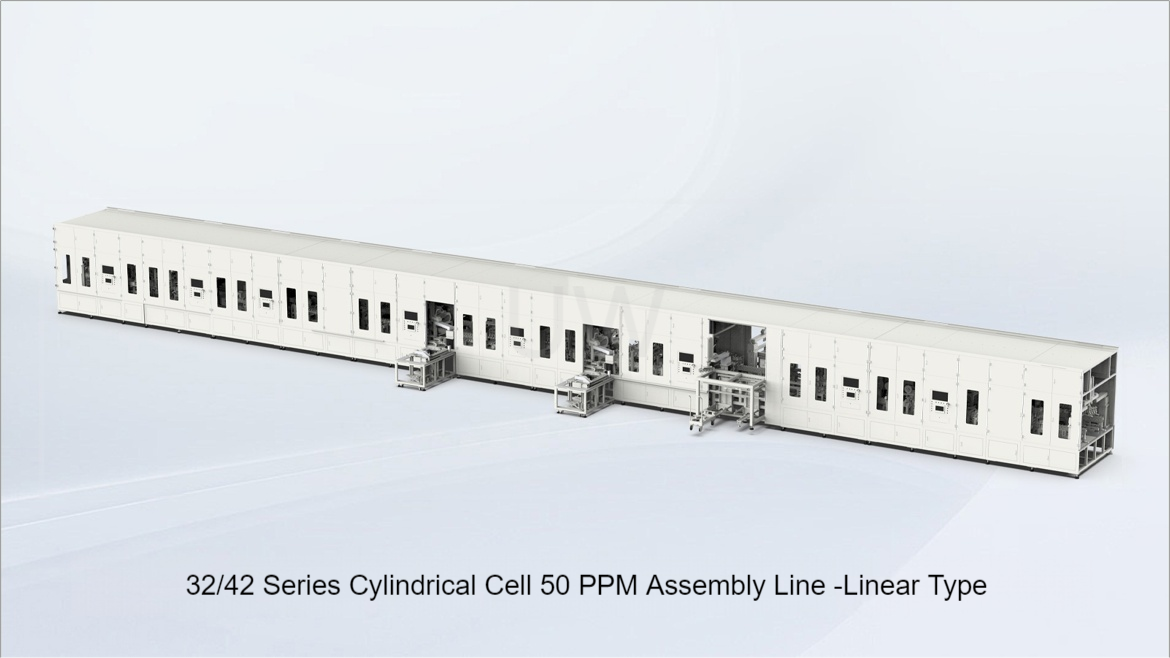

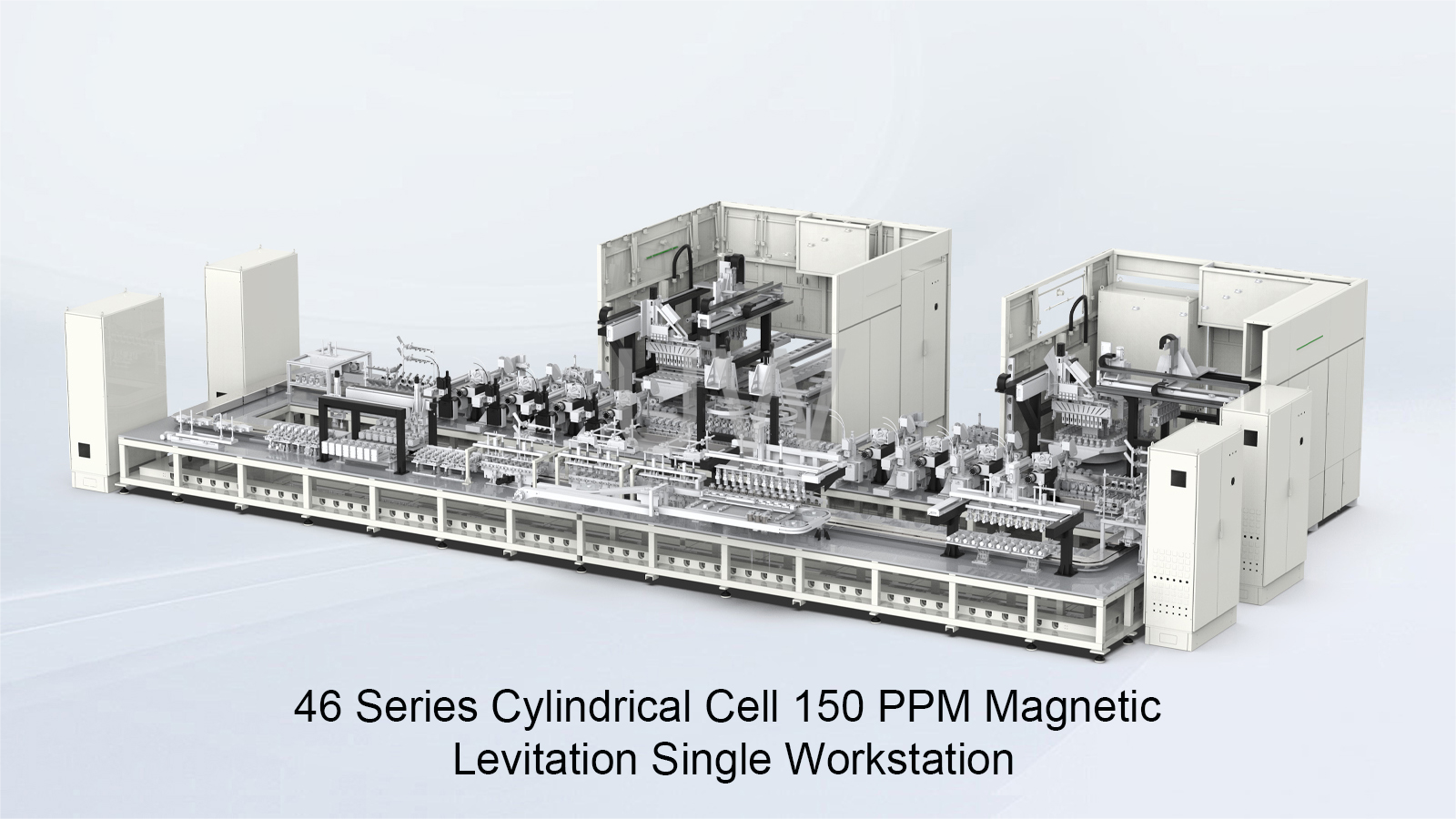

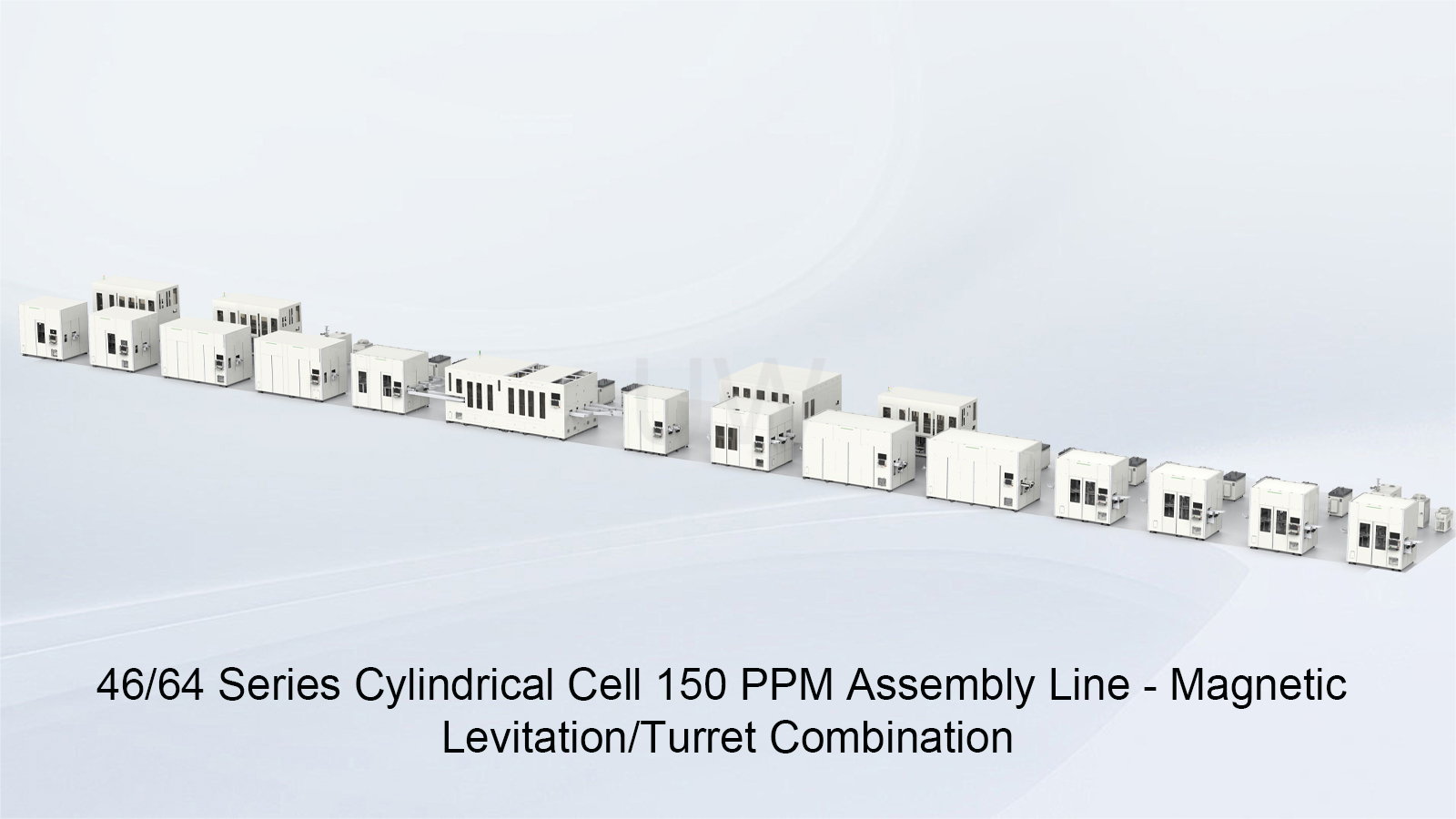

The self-developed 46 Series cylindrical cell assembly line by UW Laser offers customized solutions specifically for the power battery, energy storage battery, and supercapacitor battery industries. It has successfully served renowned companies such as CATL, BYD, Envision, Hithium, ZENERGY, and DFD. We provide various production line options, including linear, magnetic levitation, and turret-style cell production lines, with the capability to make plans according to customer needs.

Core Technological Advantages

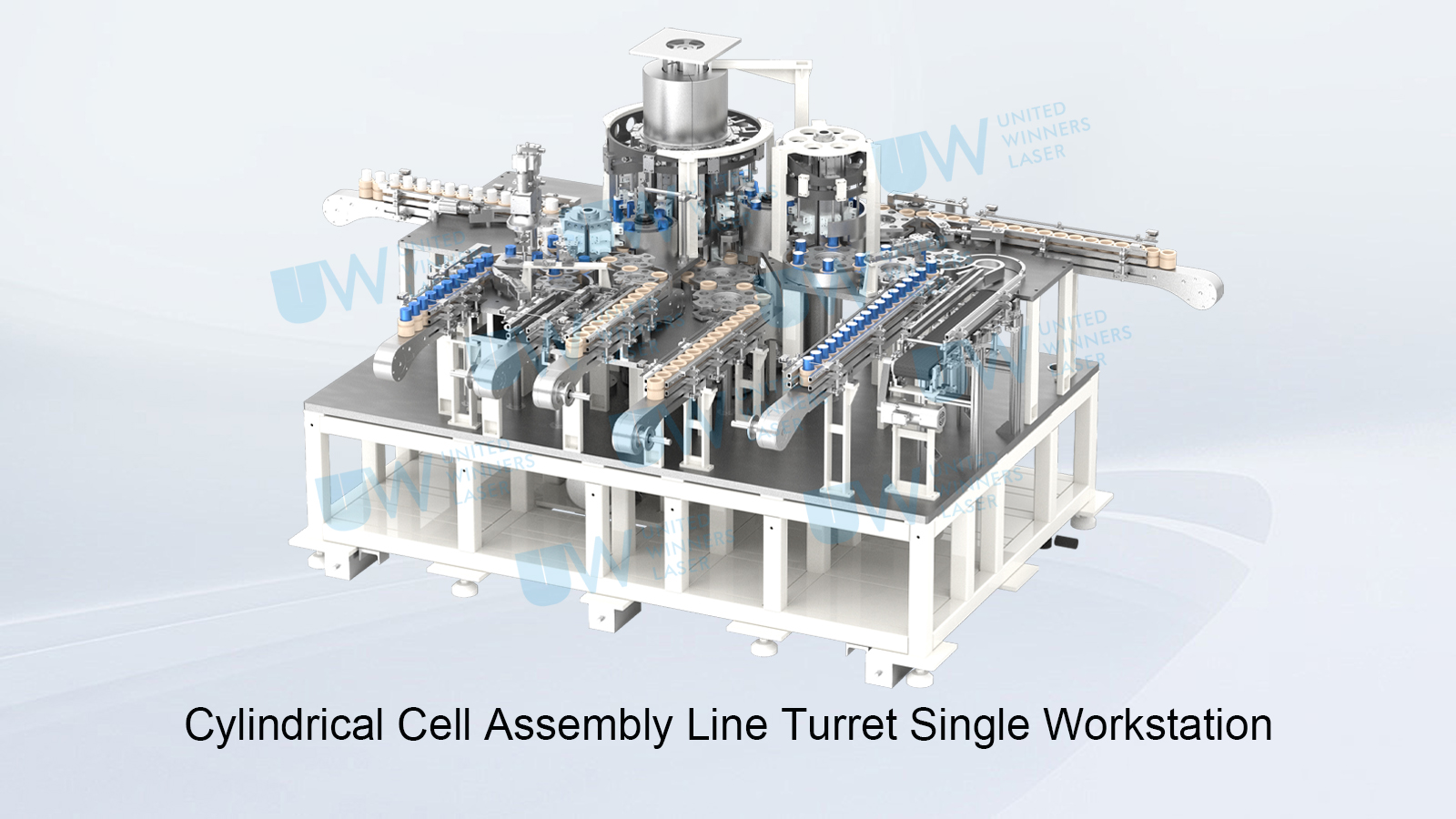

Reliability: Our turret has undergone multiple iterations, enhancing design efficiency and shortening delivery cycles while ensuring the stability and reliability of the mechanism. The application of in-process inspection technology at critical stations such as penetration welding and sealing enables real-time data monitoring during the welding process, providing a solid foundation for data analysis and quality improvement.

Uniqueness: Our welding technology, combined with turret design, achieves a laser scanner welding speed of 100-1000 mm/s, with turret repeat positioning accuracy controlled within 0.05 mm, reaching industry-leading levels. Additionally, the domestically pioneered turret flying sealing welding technology has increased the sealing welding speed to 500 mm/s.

HIgh Efficiency: The equipment design is flexible, allowing for continuous or intermittent operating modes based on production needs. In the continuous operation mode, the equipment's actual running efficiency can reach up to 300 PPM, effectively reducing production costs and enhancing market competitiveness.

Standardization: After multiple upgrades, our turret design has achieved standardized processes in design, parts processing, assembly, inspection, and debugging. This ensures that every stage, from raw materials to finished products, meets design requirements.

Stability: Featuring a cam mechanism, the equipment operates steadily with an uptime rate of over 95%, and it's simple to maintain.

Professional Team

UW Laser boasts a professional R&D team dedicated to addressing problems in the cylindrical full-tab production process. They have successfully tackled industry challenges such as flattening and sealing holes, flattening and rolling flanges, low welding efficiency, low yield rates, and low equipment uptime. UW Laser’s pioneering turret flying welding technology not only enhances production line uptime and efficiency but also greatly improves space utilization.

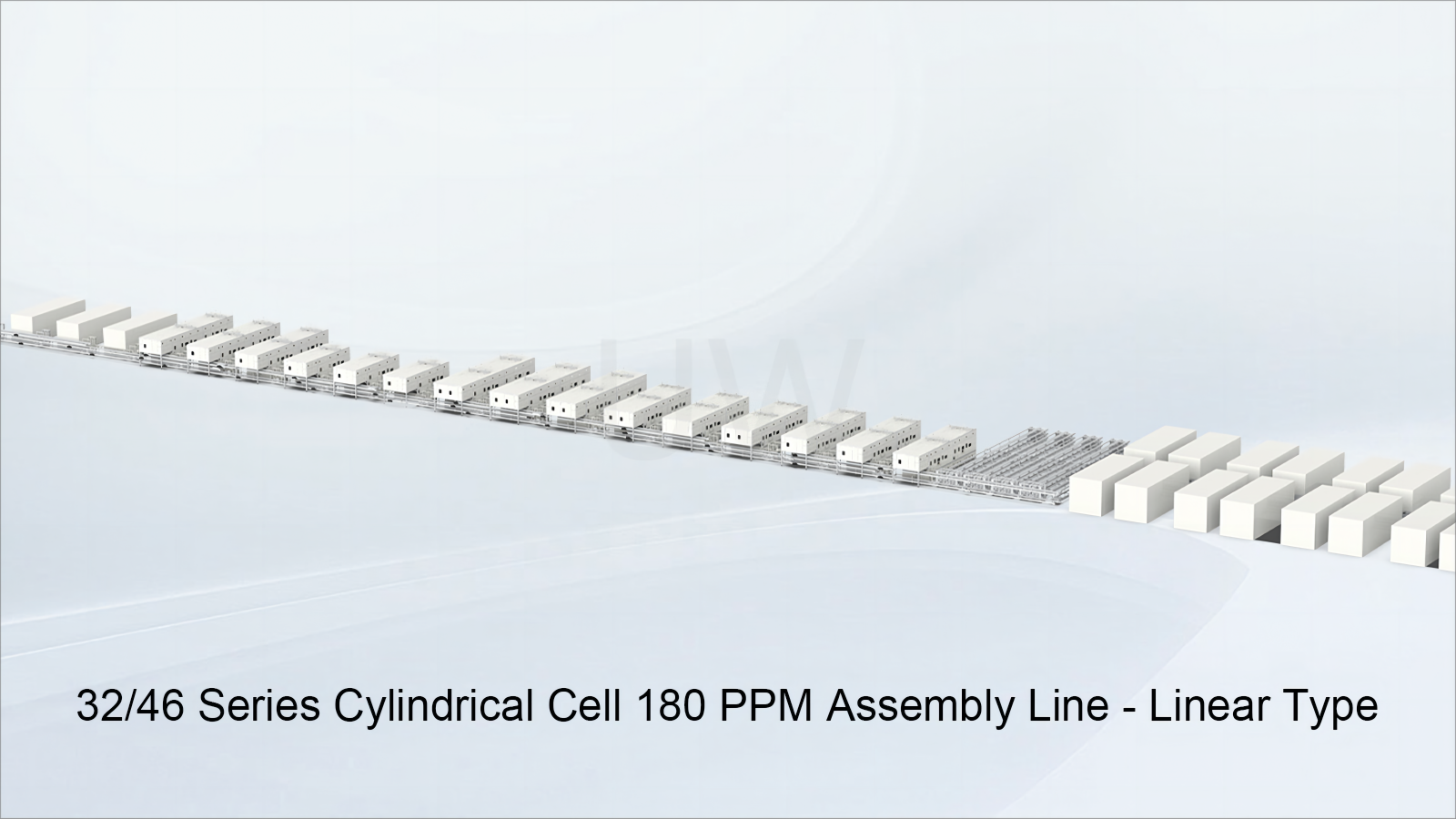

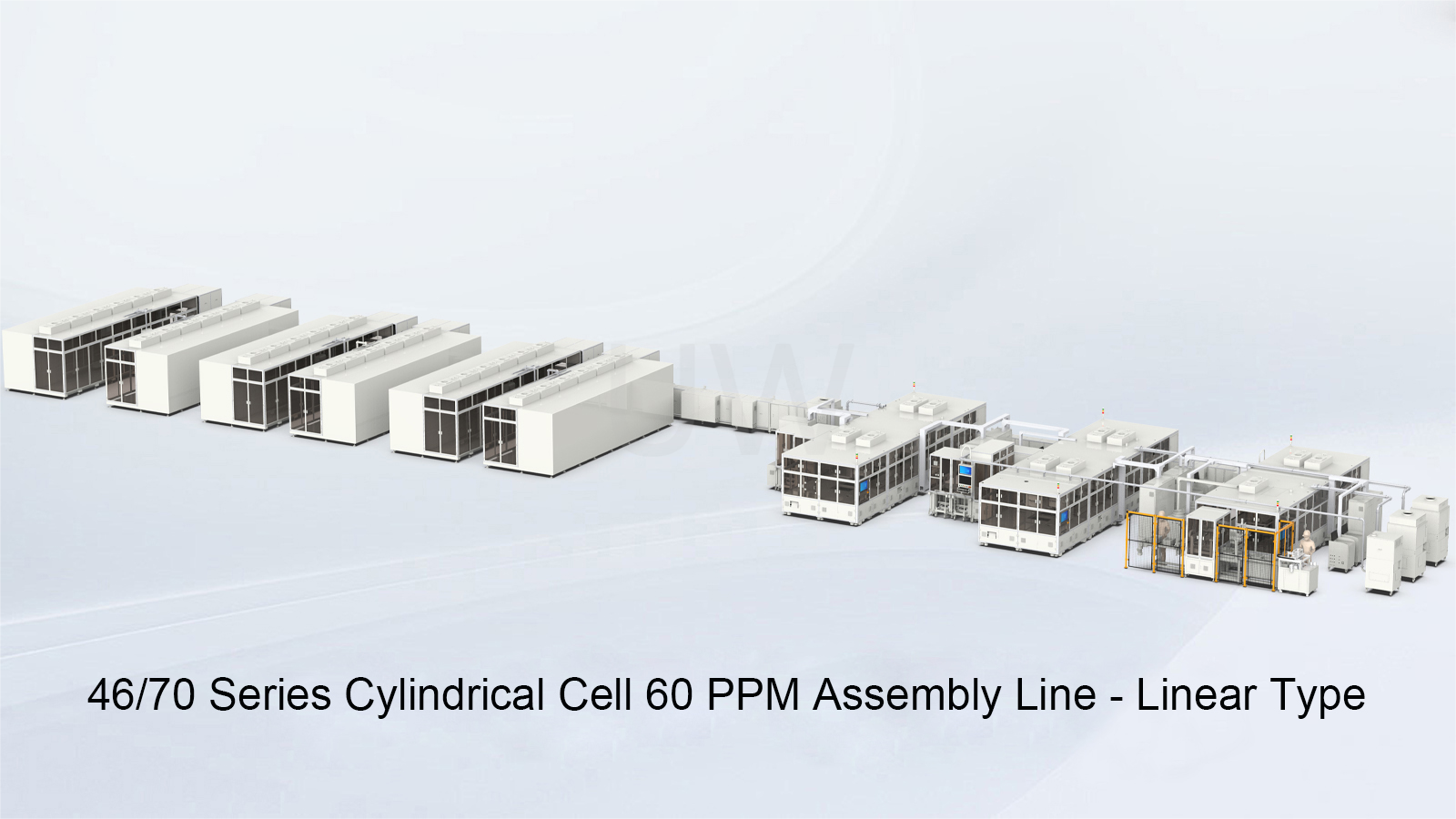

Our automated production lines cover specifications from Series 18 to Series 80, offering efficiency options from 50 PPM to 300 PPM. Additionally, we have a professional after-sales service team to ensure the optimal operating condition of our customers' production lines.

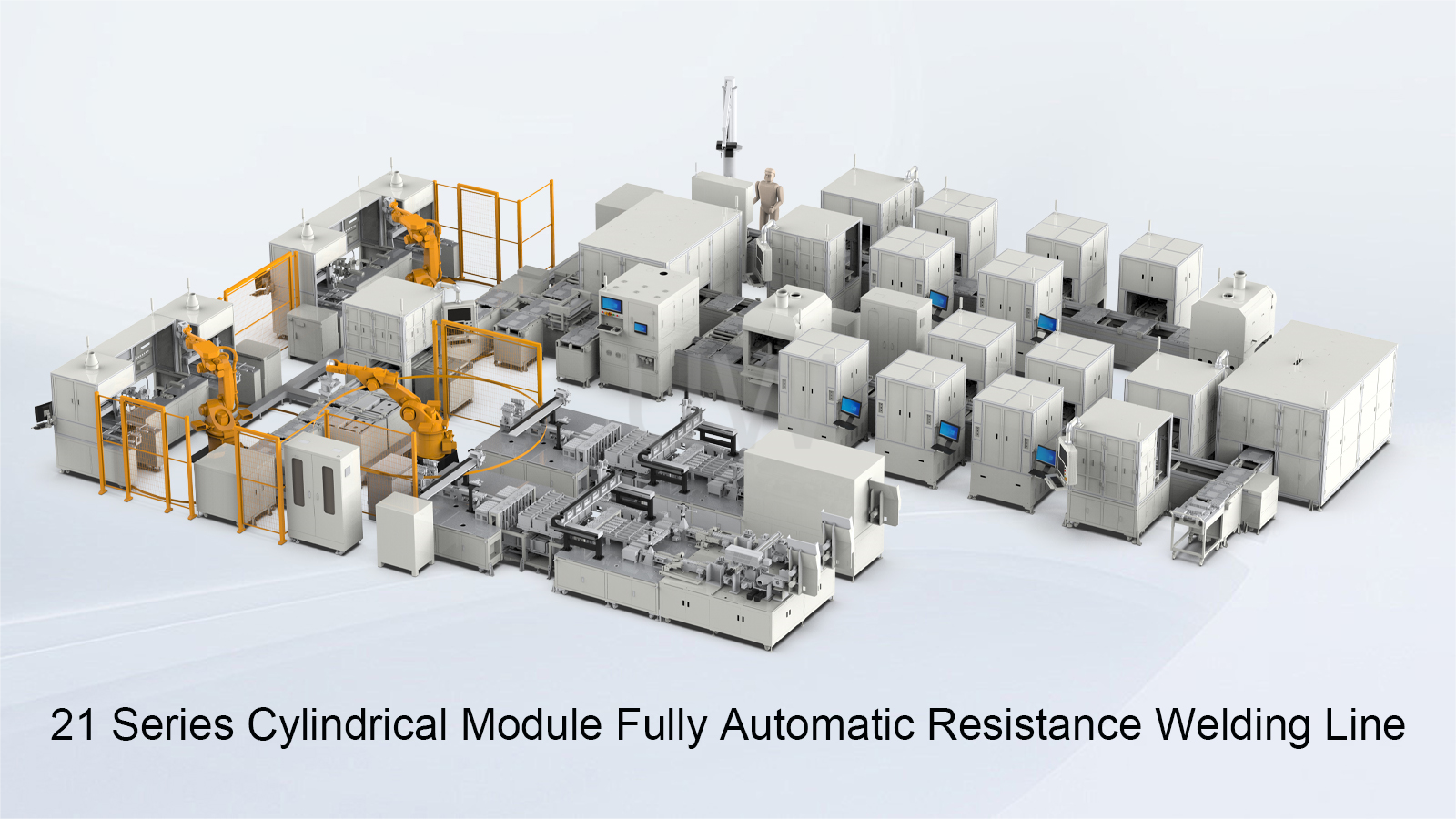

Full Series of Cylindrical Batteries

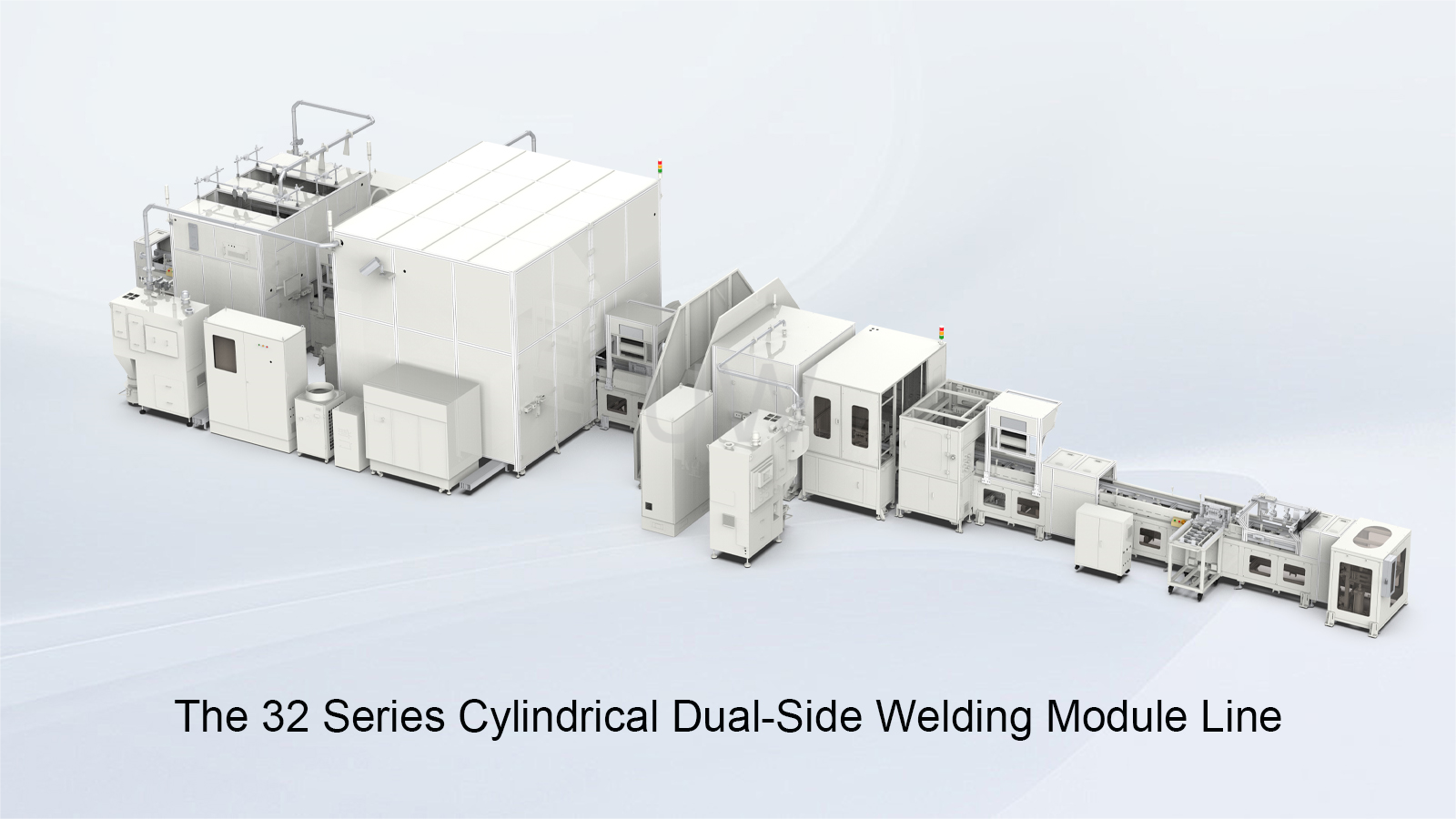

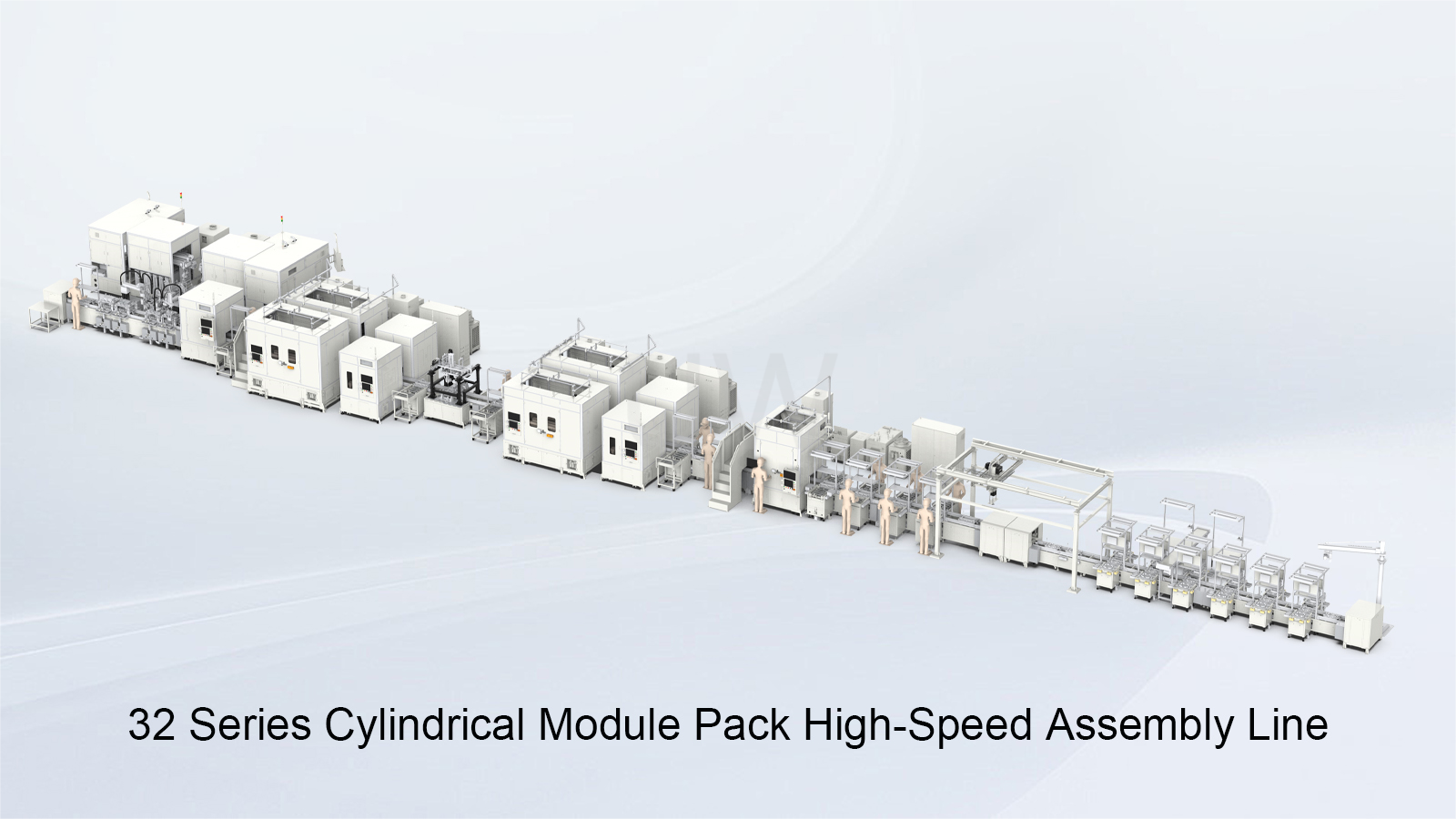

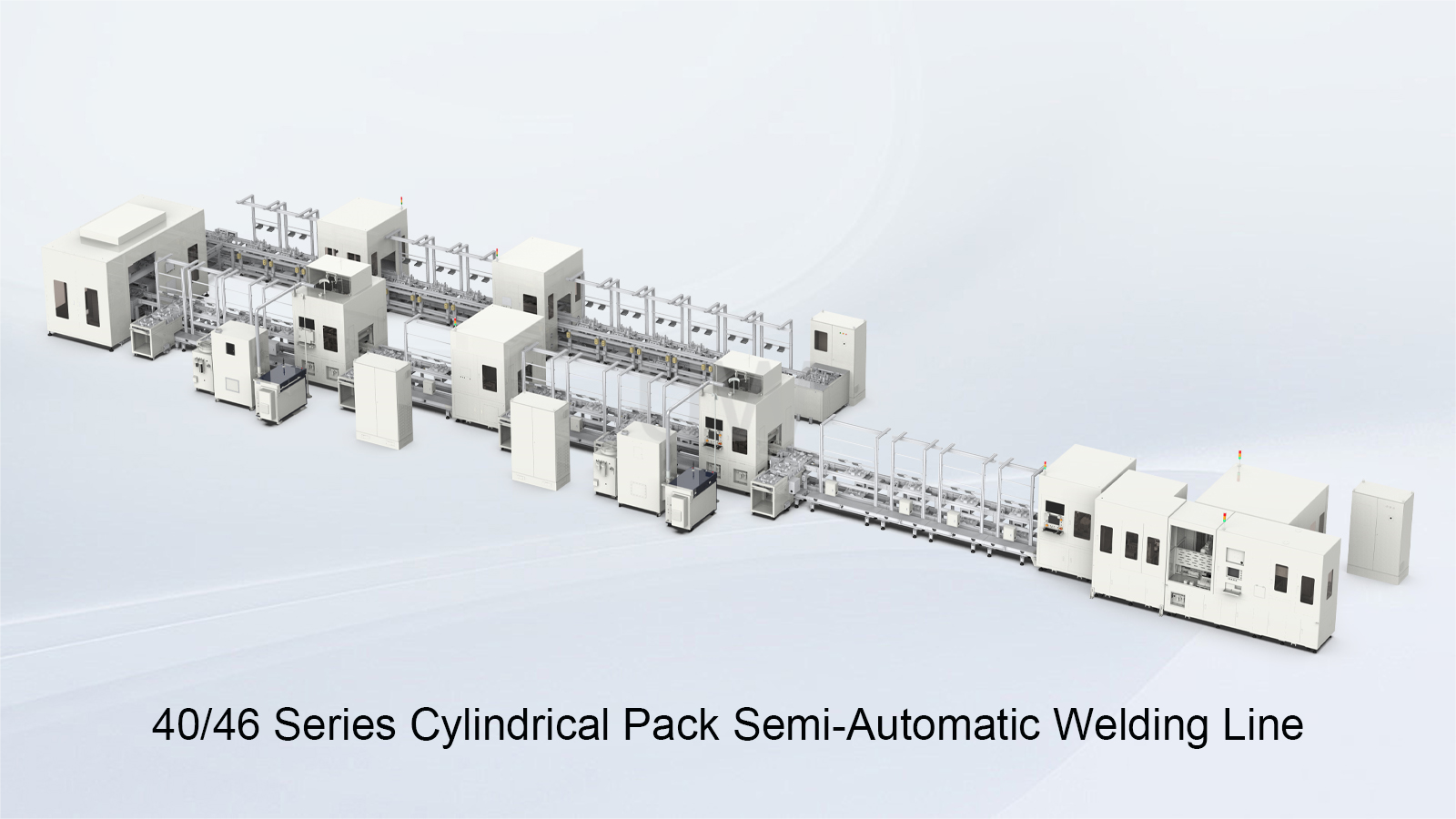

Module Pack Assembly Lines

UW Laser has the capability to design and manufacture production lines for cylindrical module Pack products, including those for start-up power supplies, communication power supplies, portable mobile power, portable electric tool power, as well as power packs for two-wheelers, light trucks, and automobiles. We have successfully achieved efficient delivery and mass production of these lines. We can provide both customized solutions and standardized production lines, ensuring precise alignment with market demands at every stage.

We offer customers a full-chain, one-stop service from cell sorting and loading to Pack unloading. In key process stages, such as sorting, glue application, cleaning, welding, and testing, we have achieved technological breakthroughs and innovations, ensuring outstanding and stable product quality.

With years of deep expertise in the design, development, debugging, and manufacturing of cylindrical module Pack production lines, we have gained widespread recognition and long-term cooperation from leading industry companies, including CATL, Deye, Chervon, EcoFlow, Gotion, and TTI.

Core Technological Advantages

Stability: Utilizing advanced modular design concepts, our production lines achieve a high degree of modularity both between machines and mechanisms. Relying on a standard module library significantly shortens the construction cycle of the production line while enhancing overall stability and reliability.

High Efficiency: For large cylindrical modules, we have achieved a production efficiency of up to 240 PPM. Through innovative technologies such as component section turrets and flying welding in the welding section, we have developed a unique and highly efficient solution in the industry.

High Flexibility: Utilizing design concepts such as variable pitch, quick insertion, pallet flipping, and quick-release test connectors, it enables rapid compatibility and flexible adjustments to meet diverse production needs.

Uniqueness: In welding processes, comprehensive detection configurations before, during, and after welding ensure precise control of welding quality, with the welding yield rate of up to 99.95%, setting new standards in the industry.

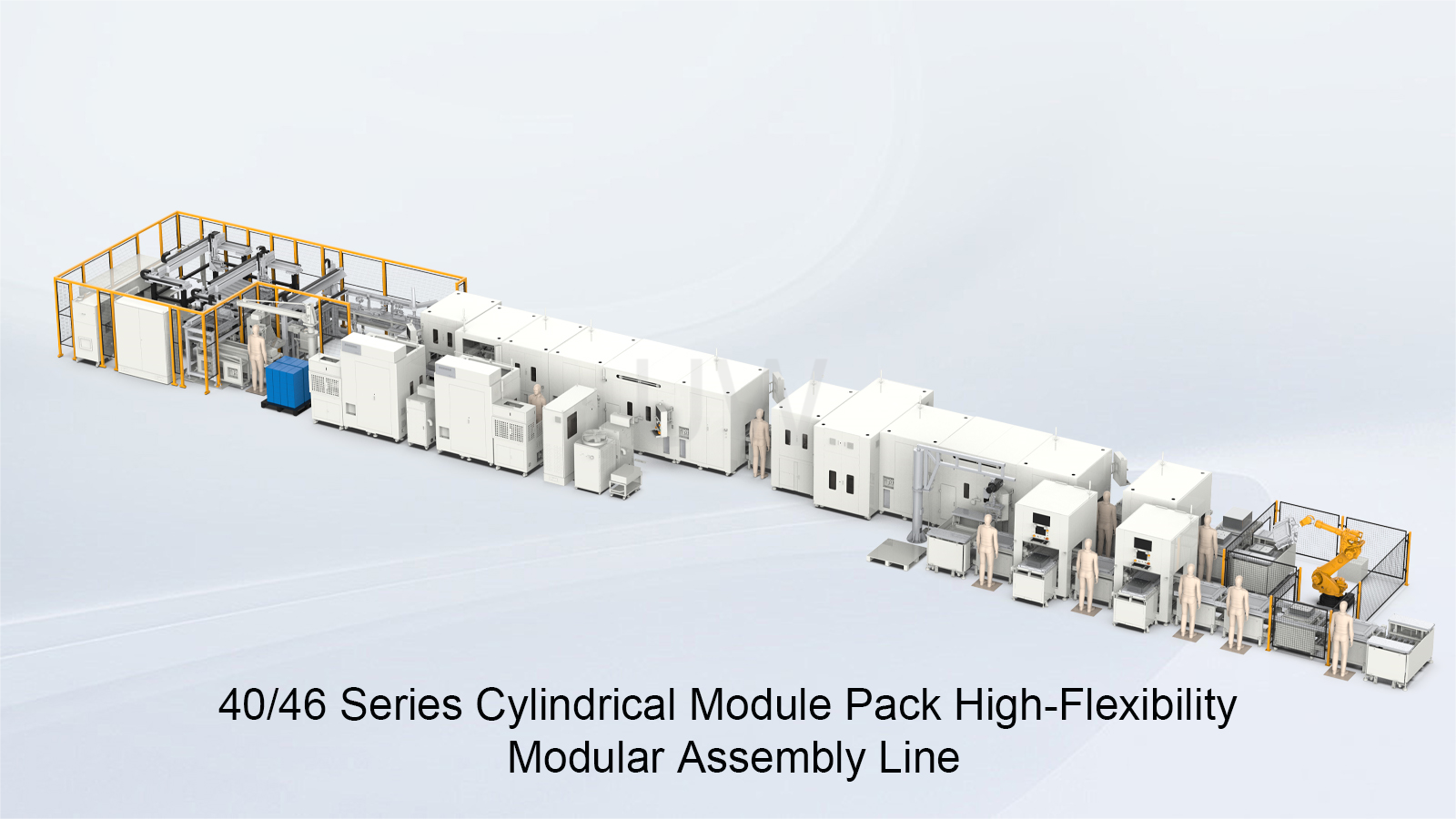

Pack 40 Series Cylindrical Module Pack

High-Flexibility Modular Assembly Line

The high-flexibility module Pack production line of UW Laser adopts an innovative modular design concept. Through a refined process layout, the Pack assembly process is divided into multiple specialized workstations, including cell sorting, Block grouping, stacking, glue application, curing, leakage testing, and welding.

This modular design allows Pack products with different process requirements to flexibly select the corresponding modules for efficient assembly. It enables co-line production, meets diverse product needs, and greatly enhances the flexibility and adaptability of the production line.

Core Technological Advantages

High Flexibility: The production line employs advanced functional module design, with modules connected through AGVs or conveyor sysytems. Each module can operate independently or collaborate with other modules. The system intelligently selects functional modules, allowing products to autonomously choose production paths based on system planning. It ensures high flexibility and product adaptability in the production process, while reducing customers' investment costs and space requirements.

High Efficiency: The cell sorting module uses efficient turret sorting technology, with a single machine sorting efficiency exceeding 150 PPM. This enhances the overall efficiency of the production line and improves equipment utilization rates, ensuring continuity and stability in production. The welding workstation is equipped with laser scanner welding technology, which further boosts production efficiency and reduces manufacturing costs.

Safety: The welding station is equipped with emergency explosion-proof boxes and smoke detection devices, enabling in-station detection and external handling to ensure the safety of the production process.

Laser Scanner Welding

UW Laser Patent

This technology, as an invention patent of UW Laser, is widely used in key processes such as cell collector plate welding, turret sealing welding, and module Pack busbar welding.

During the product handling process, the laser welding head can move with the product, achieving a welding speed of up to 500 mm/s and a laser utilization rate of over 70%. This technology features high welding efficiency, minimal heat generation, and reduced welding distortion. It not only significantly enhances welding efficiency but also ensures consistency in welding quality

UW Laser is committed to providing efficient, reliable, and stable intelligent manufacturing solutions through continuous technological innovation and optimization, supporting customers' long-term development in the new energy sector.