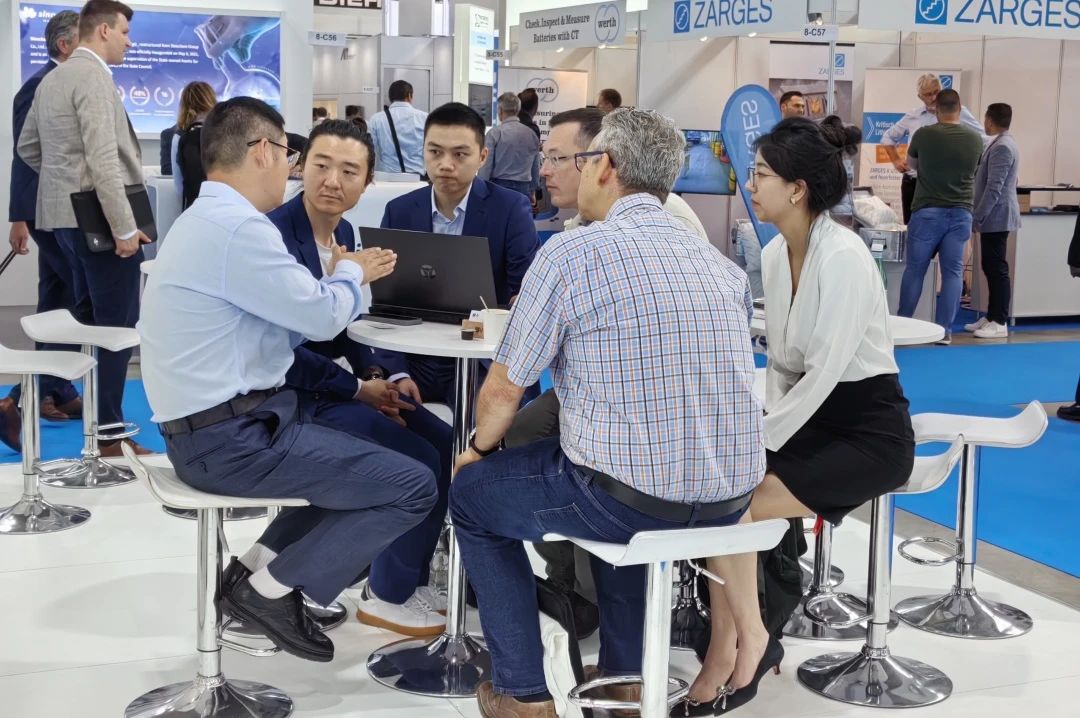

On June 18th local time, the Battery Show Europe 2024 grandly opened at Messe Stuttgart in Germany, gathering 1,000+ battery industry manufacturers. UW Laser showcased its cutting-edge products at Booth 8-C60. It showcased comprehensive solutions for new energy, including lithium battery manufacturing, module/pack assembly, new energy electric drive intelligent production lines, MES smart factories, and hydrogen equipment, demonstrating "Intelligent Manufacturing" laser welding to global customers.

Global Energy Gathering

China's Brand of "Intelligent Manufacturing" Laser Welding

In recent years, with the explosive growth of the European new energy vehicle market, the demand for power batteries has also increased significantly. Europe's extensive plans for power battery production capacity and its large market scale provide excellent development opportunities for highly competitive equipment companies in the global battery industry. UW Laser is accelerating its overseas expansion amidst the vigorous growth of China's lithium battery exports, committed to establishing "China's brand" for complete production line equipment for the new energy battery manufacturing.

In the field of new energy battery equipment, UW Laser has achieved mainstream battery process coverage including prismatic, cylindrical, and pouch formats. It possesses high-speed laser cutting and slitting integrated machines, slitting and stacking integrated machines, prismatic cover lid assembly lines, prismatic cell assembly lines, cylindrical battery assembly lines, prismatic power module pack production lines, prismatic energy storage module pack production lines, pouch module pack lines, cylindrical module pack lines, CCS automatic assembly welding lines, and electric control and drive production lines. It has provided integrated solutions for the mid-to-late stages of batteries to over a thousand global new energy battery enterprises, with cooperative clients including CATL, BYD, EVE, and other leading lithium battery companies.

Prismatic Cells Assembly Line

Prismatic cells assembly line includes die cutting equipment, preheating tunnel furnace equipment, hot pressing equipment, X-ray inspection equipment, and tab pre-welding matching equipment. Apart from manual feeding assistance, the operations are fully automated with continuous data recording. Standardized product design and modular production enable compatibility with various cell models ranging from 50AH to 280AH, facilitating rapid changeovers. Additionally, it features low energy consumption and stable operation.

Blade Cell Assembly Line

The blade cell assembly line is a modernized production line designed specifically for blade battery production.It is characterized by high efficiency, stability, strong compatibility, and advanced technological applications.This line covers processes such as cathode and anode ultrasonic pre-welding, cell lids marking, cathode and anode tab welding, Mylar wrapping and hot melting, shell insertion, laser pre-welding of cathode and anode top covers, laser full welding of cathode and anode shells, Hi-pot testing, leakage detection, sealing welding of injection holes, and tape marking.

Cylindrical Cell Five-in-One Welding Station

Cylindrical cell five-in-one welding station calls the corresponding recipe based on the incoming material status, shielding other fixtures with blocking devices, and using corresponding fixtures to achieve different laser welding processes. It includes welding of positive and negative current collectors, end cover sealing welding, and penetration welding of positive and negative electrodes. Compatible with five laser welding processes, the single-machine efficiency can reach 60 PPM.

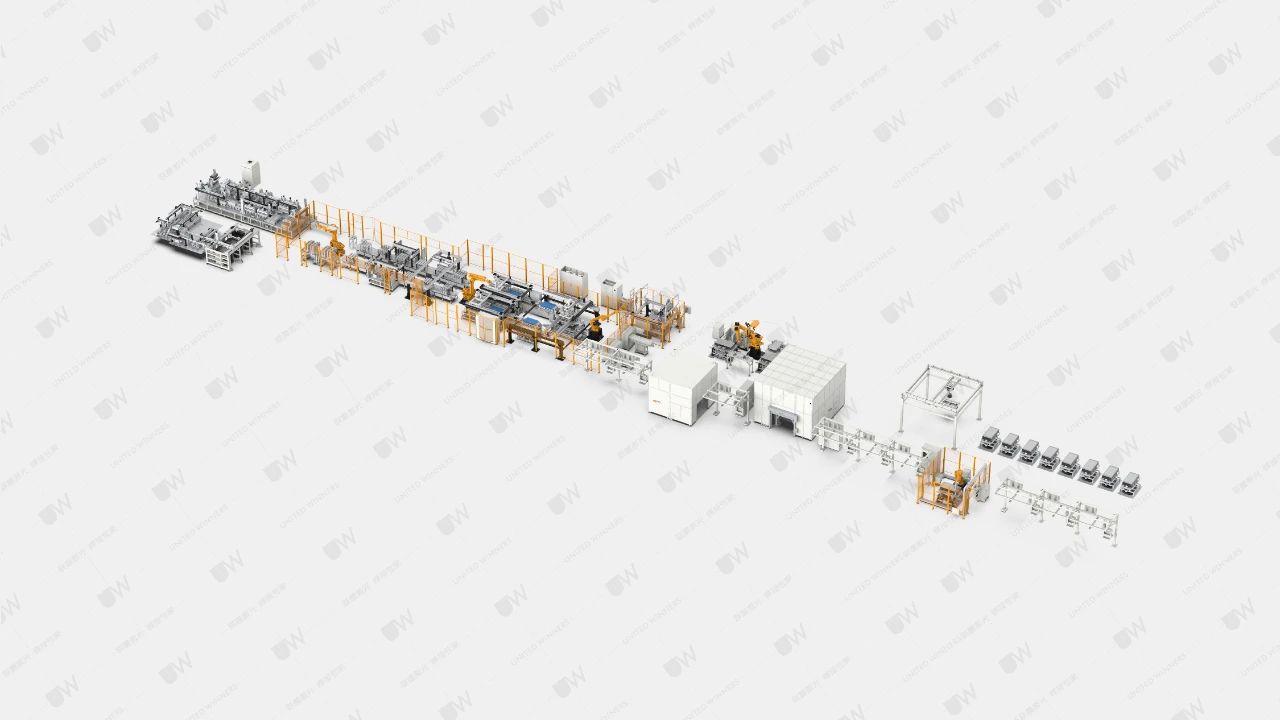

Prismatic Energy Storage Module PACK Production Line

The Prismatic Energy Storage Module PACK production line includes the energy storage liquid & air cooling prismatic module PACK line, energy storage liquid-cooling prismatic module PACK line, and energy storage container PACK line.

Energy Storage Liquid & Air Cooling Prismatic Module PACK Line. It achieves production from cell handling to PACK finished products, compatible with liquid-cooling and air-cooling structure module production lines. High automation can be achieved, with the efficiency up to 20 ppm and producing cells of 150ah, 280ah, and 314ah.

Energy Storage Liquid Cooling Prismatic Module PACK Line. It achieves production from prismatic cell handling to PACK finished products, cells of 380mm and 580mm. High automation can be achieved with the efficiency up to 20 ppm.

Energy Storage Container PACK Line can achieve fully automated PACK stock-in, stock-out, transportation, and containerization; covering industrial and commercial energy storage, and large-scale energy storage.

Explore Overseas Market

Leading the Way to the Battery Industry

Back in 2012, UW Laser entered the Japanese market. Through rapid growth and expansion, by 2020, it had successfully listed on China's STAR Market, becoming the leading brand in laser welding domestically and establishing itself as one of the few global companies with a complete industry chain encompassing lasers, automation control, and welding processes. UW Laser has established subsidiaries in Japan, Germany, and the United States, along with a sales and after-sales service center in India. With a global perspective, its products are well-received and trusted by over 1,680 enterprises worldwide.

In 2023, China's exports of new energy vehicles, lithium batteries, and photovoltaic products, the "new three items," grew nearly 30%, marking a shift from "Made in China" to "Created in China." Europe has emerged as a hotbed for global lithium battery industry competition, boasting vast market potential. Germany, at the heart of the overseas electrification wave, is pivotal in Europe. At the Battery Show Europe 2024, UW Laser not only showcased advanced equipment and technological achievements for European clients in the new energy sector but also leveraged the exhibition to better connect with the European market to provide better service for customers.

"March forward triumphantly, undeterred by long distance; seize the momentum, unbounded by time." With nearly 20 years' industry experience, UW Laser has leveraged its outstanding intelligent manufacturing solutions in laser welding and innovative technological strength. It simutaneously develops domestic and international markets, contributing to the stable and sustainable development of global green energy solutions.