UW Laser’s R&D team has invented a YAG + semiconductor multi-wavelength hybrid welding technology, which combines the infrared laser generated by the YAG laser with the semiconductor laser through the multi-wavelength hybrid welding head, so that the axes of the two laser beams overlap in space. The method retains the advantages of good energy stability of a single-pulse YAG laser and achieves more than two times the overall efficiency of existing seal pin welding on the basis of guaranteed seal pin welding yields through the combination with the semiconductor laser heat source.

The seal pin welding, also known as liquid injection port welding, is a process where the electrolyte is injected into the battery and immediately sealed by laser welding with a rubber plug, thus isolating the entire core from the external environment and forming an airtight electrochemical system for the whole core. Completing this process means a complete battery cell is basically made, so the welding excellence rate is crucial. Cracks, explosion points, and pinholes can affect the stability and safety of the entire battery.

The shape of the seal pin is usually a round cap with a diameter of about 8mm and a thickness of about 0.9mm. At present, the welding methods of seal pins mainly include pulsed laser welding, fiber laser welding, and continuous hybrid laser welding.

▲ Seal Pins of Hybrid Laser Welding

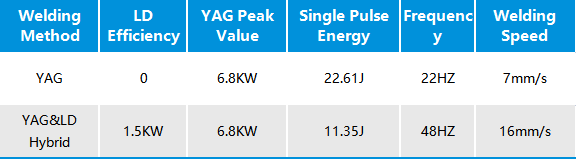

The pulse laser welding seam is beautiful in shape, excellent in consistency, high in yield, and achieves a first-time welding rate of ≥99.5%. However, since the maximum power of the YAG pulse laser on the market is 600W, the maximum welding speed is only 7mm/s due to the power limitation. Fiber and continuous hybrid laser welding are more efficient and have a high welding speed of up to 80mm/s but a lower excellent rate than pulse laser welding.

With the accelerated expansion of global power battery production capacity and the continuous promotion of intelligent manufacturing, the large-scale production capacity of power battery companies has put forward higher requirements on the production efficiency and quality of the production line and also raised higher challenges to the welding efficiency and quality of the seal pins.

YAG VS YAG&LD Hybrid Experimental data

The YAG pulse + semiconductor multi-wavelength hybrid welding technology invented by the UW Laser R&D team perfectly solves the problem of sealing nail welding efficiency on the basis of ensuring a high-quality rate. After numerous experimental verification, the YAG pulse + semiconductor multi-wavelength hybrid welding technology can achieve a high seal pin welding excellent rate of ≥99.5% and speed of 16mm/s, which is more than twice the original!

As a core supplier of the new energy power battery across the industry, UW Laser continues to enrich the laser welding and intelligent manufacturing solutions while deepening the innovation and upgrading of key technologies for power battery equipment manufacturing. The upgrade of seal pin welding technology will enhance the performance and advantages of power battery equipment and manufacturing solutions and bring greater value to global power battery customers!