Laser cleaning is known as the "21st century the most promising green cleaning technology", which can change the grain structure and orientation of the substrate surface without damaging the substrate surface, and can control the surface roughness of the substrate, thereby enhancing the comprehensive performance of the substrate surface. Along with the accelerated industrialization process and the steady progress of the "dual carbon" goal, it has gradually replaced the traditional cleaning process in many fields and has gradually become an indispensable equipment manufacturing technology in high-end manufacturing fields such as industry, military industry, shipbuilding, aerospace, etc.

The concept of laser cleaning originated in the mid-1980s, and its principle is to ultilize the laser beam’s characteristics of large energy density, controllable direction, and strong convergence ability so that the pollutants (including the oil, rust, dust slag, coatings, oxide layers, film layers, and so on) interact to instantaneous heat expansion, melting, gas volatilization and other forms of separation from the workpiece substrate.

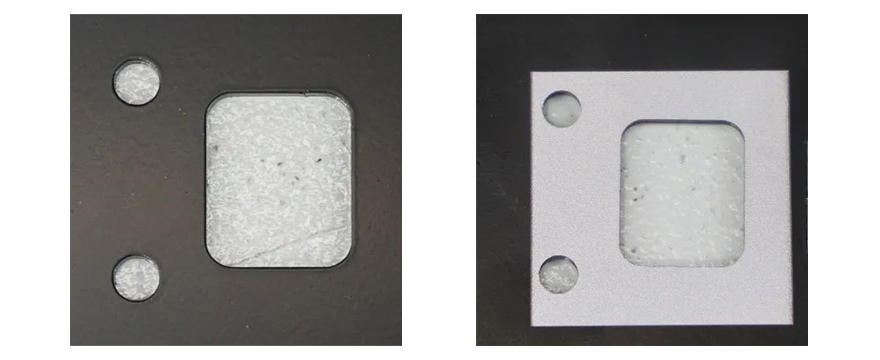

Before and After Laser Cleaning

The entire laser cleaning process is complicated and can be roughly divided into laser gasification decomposition, laser dissection, thermal expansion of pollutant particles, substrate surface vibration, and pollutant detachment. At present, the cleaning methods are mainly laser ablation, liquid film-assisted laser, and laser shock wave, which can stably and effectively clean the surface of various regular substrates, including metals, alloys, glasses, and various composite materials.

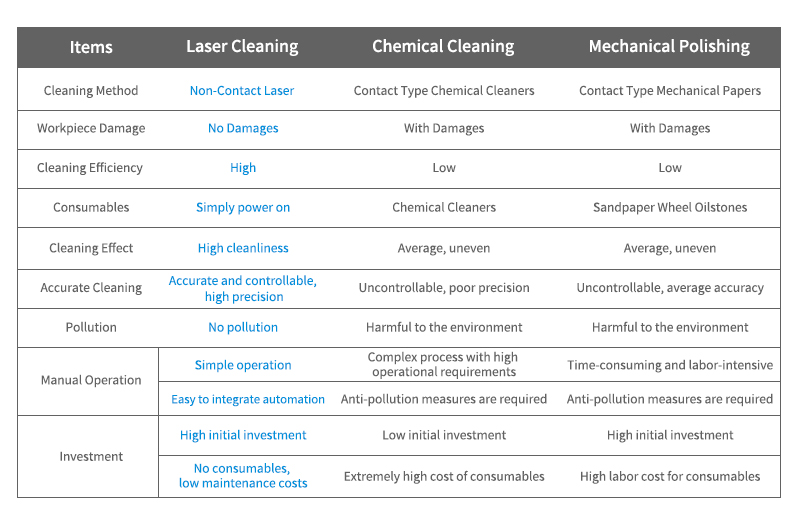

Advantages of the Laser Cleaning Technology

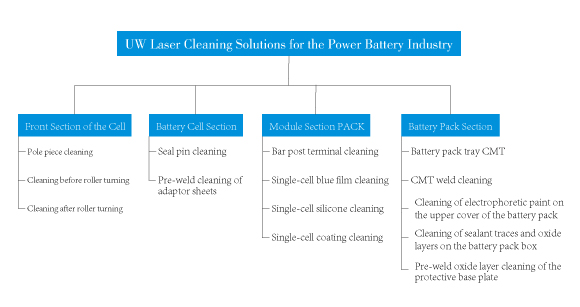

Applications of Laser Cleaning in the Intelligent Manufacturing of Lithium Batteries

At present, laser cleaning has become the main means of battery surface treatment and is widely used in three main power battery production processes: pole piece manufacturing, battery cell manufacturing, and battery assembly. The battery manufacturing process has been greatly improved by using lasers, cleaning heads, control software, and computer integrated control.

1、Laser Cleaning of Pole Pieces

The positive and negative collectors require the thin metal strip to be cleaned when coating the electrode material. The common positive collector is aluminum foil, and the negative collector is copper foil. To ensure the stability of the collector inside the battery, the purity of the two is required to be above 98%.

Traditional wet ethanol cleaning is easy to cause damage to other components of lithium batteries. Using laser cleaning metal foil can not only improve the efficiency of the cleaning process and save cleaning resources, but also establish real-time monitoring of cleaning process data and quantitative determination of cleaning results, which can effectively improve the production consistency of the number of pole pieces.

2、Pre-Weld Laser Cleaning of Batteries

In recent years, laser welding has become the standard for power battery production lines and is widely used in the welding of power battery tabs, seal pins, bus bars, battery modules, etc. A clean and uniform surface is the basic prerequisite for achieving successful and durable welding and bonding. Therefore, surface treatment is performed on each welding part before welding to remove contaminants at the weld joints, which can effectively improve welding quality and reduce costs.

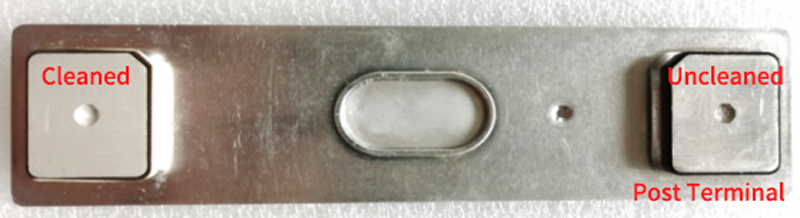

Post Terminal Cleaning

Laser cleaning is also used for cleaning seal pins, adapter sheets, bar poles in the module section, single-cell blue films, single-cell silica gels, and single-cell coatings, effectively removing dirt and dust on each end face to prepare for battery welding in advance and reduce defective welding products.

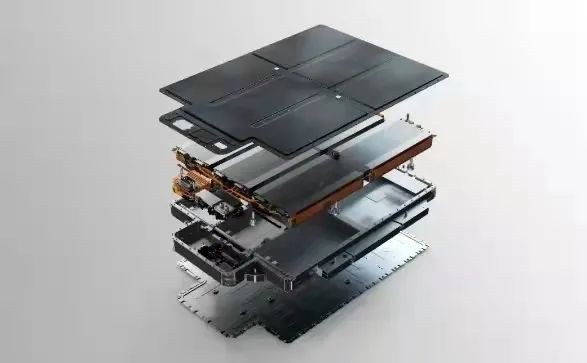

3、Laser Cleaning During Battery Assembly

In order to prevent accidents, the lithium battery cells are often treated with external glue to play an insulating role, prevent short circuits, protect circuits, and prevent scratches.

Oxide Layer Cleaning of Battery Tray Welds

Laser cleaning is performed on the CMT welding seam of the battery pack tray, the electrophoretic paint on the upper cover of the battery pack, the oxide layer of sealant traces of the battery pack box, and the oxide layer of the protective bottom plate before welding, so as to improve the adhesion of the paste or coating glue. It will not produce harmful pollutants, and this eco-friendly cleaning method will become more and more important in the case of high attention to environmental protection.

Based on the advantages of R&D and customers in the battery sector, UW Laser began to extend the battery laser cleaning business vertically many years ago and obtained high-efficiency laser cleaning technologies. The company can provide customers with stable and efficient laser cleaning solutions for the CMT welding seam of the battery pack tray, the electrophoretic paint on the upper cover of the battery pack, the oxide layer of sealant traces of the battery pack box, and the oxide layer of the protective bottom plate, and so on.

Applications of UW Laser Cleaning Solutions Across the Power Battery Industry

100% Excellence Rate

Ideal for Battery Pack Cover Cleaning

Electrophoretic paint gives the cover a certain decoration and provides anti-corrosion protection, such as anti-rust, anti-impact, anti-corrosion, etc. However, due to some special requirements, it needs to be electrophoresed again, so the electrophoretic paint film should be removed.

Image Source: 699PIC.Com

The current mass production of top covers mainly uses metal stamping methods, in which the stamping oil is used in the production process and needs to be cleaned after production.

At the same time, batch cleaning is a perfect solution for rust removal, oil removal, and tackling metal particles, dust, etc. It is ideal for cleaning the battery pack cover with the characteristics of automation, no contact, no polluting, high precision, no damage or small damage, etc.

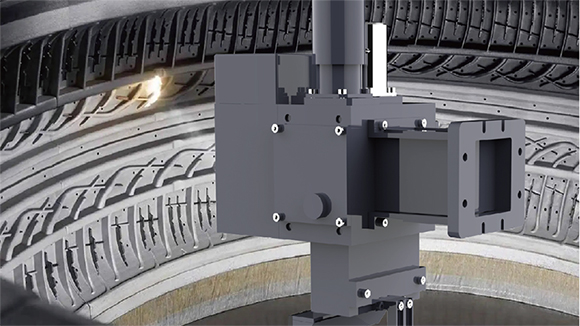

Laser Cleaning Workstation for Power Battery Case Covers Developed by UW Laser

The laser cleaning workstation for power battery box covers self-developed by UW Laser is applicable to the laser cleaning of the electrophoretic paint coating on battery box covers. Its shrapnel clamp structure realizes independent pressing at up to 108 compact positions. The cleaning focal length is controlled by a galvanometer equipped with a high-precision robot and a laser rangefinder to achieve 100% excellence rate without damaging the galvanized layer under the electrophoretic coating.

At the same time, batch cleaning is a perfect solution for rust removal, oil removal, and tackling metal particles, dust, etc. It is ideal for cleaning the battery pack cover with the characteristics of automation, no contact, no polluting, high precision, no damage or small damage, etc.

1、Equipped with a self-developed handheld laser cleaning machine to enable dual application options of manual handheld / with robotic automation .

2、It can clean coatings as thick as 0.035mm with no damage to the galvanized layer under the electrophoretic coating to achieve a 100% cleaning excellence rate.

3、The special aluminum alloy laser housing is adopted, which is easy to disassemble and maintain.

Before and After Laser Cleaning

A new round of large-scale manufacturing of lithium batteries has been launched, and the new round requires higher quality consistency and higher precision of process control. UW Laser insists on starting from laser welding and intelligent manufacturing and is customer-oriented. The company also insists on pioneering and innovation to solve customers' welding and cleaning problems and is committed to providing customers with perfect intelligent equipment manufacturing solutions.