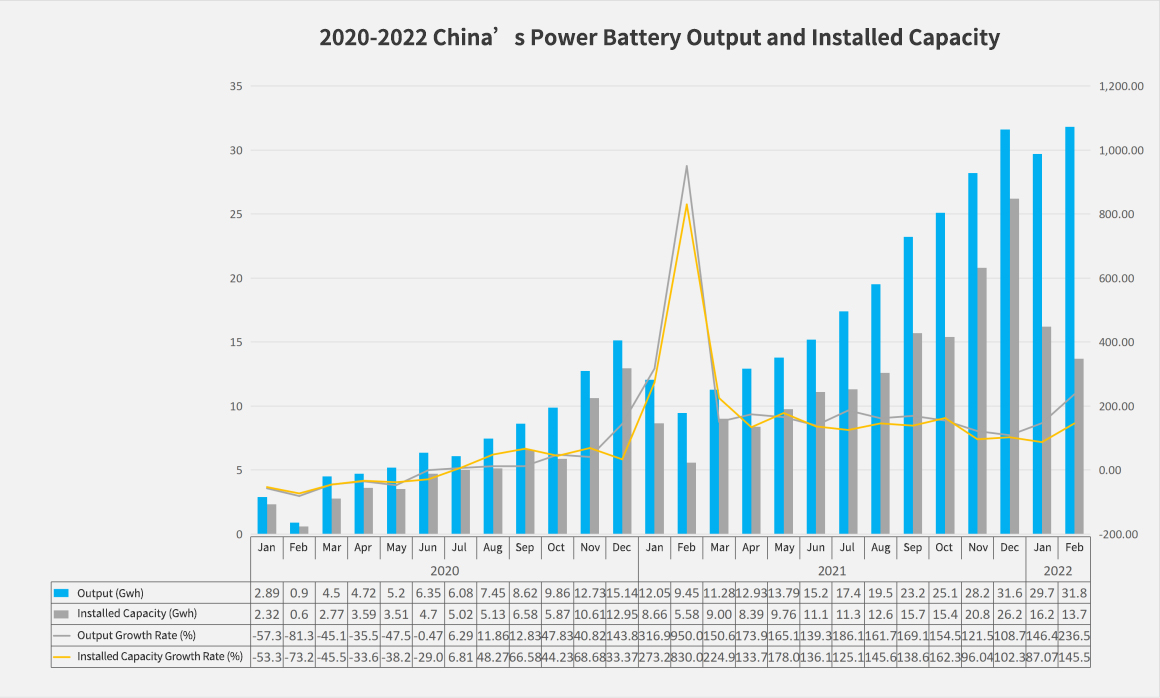

Power battery refers to a rechargeable battery system used in new energy vehicles to provide power sources. Under China's "carbon peaking and carbon neutrality" goals, the development of new energy vehicles is further accelerated and has become a new growth point for the auto industry. New energy vehicles have changed traditional vehicles' supply systems, and their core technologies are of three types: motor, battery, and electronic control system. In recent years, driven by various factors such as policies and markets, the development of the new energy vehicle's power batteries has accelerated. Especially after the recovery of the new energy vehicle market, which was hit hard by the Covid-19 pandemic, China's power battery industry has thereafter "turned the tide."

Data Source: China Automotive Power Battery Industry Innovation Alliance

Power Battery Production Line Standard

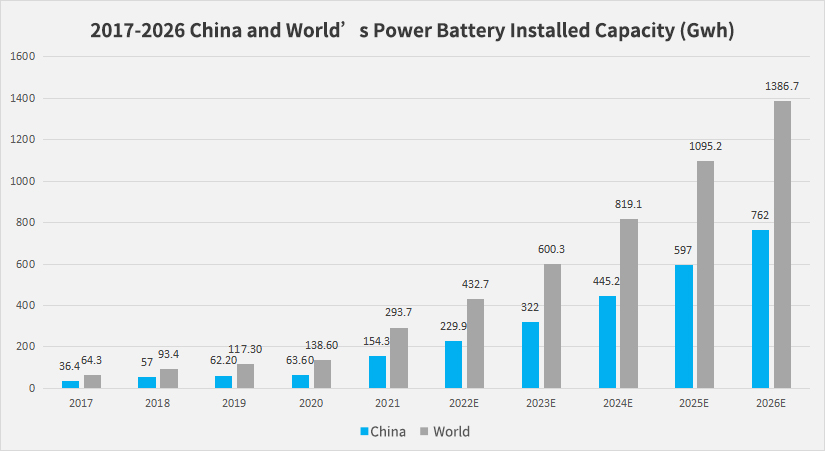

China is the largest power battery market, mainly because it has the largest new energy vehicle consumer market, the most complete power battery industry chain, a complete policy support system, and many outstanding enterprises with international competitiveness, which enables China's complete industry chain to group out of overseas. According to the China Automotive Power Battery Industry Innovation Alliance, between 2017 and 2021, China's installed power battery capacity grew at a compound annual growth rate of 43.5%, reaching 154.5 GWh in 2021. With the rapid growth of new energy vehicle penetration, the healthy development of the industry chain, and the effective control of the Covid-19 pandemic, China's installed power battery capacity is expected to reach 762.0 GWh in 2026.

Data Source: China Automotive Power Battery Industry Innovation Alliance

The power battery manufacturing process is complex. Under the demand for energy-saving and high-efficiency intelligent manufacturing and continuous improvement of power battery safety performance, laser welding with the advantages of high capacity density, high automation capability, and strong flexibility has become the standard configuration of power battery production lines. It is also widely used to the welding of power battery tabs, cell shells, seal pins, soft connections, bus bars, explosion-proof valves, battery modules, and packs so that the safety and service life of power batteries are greatly improved.

In 2021, UW Laser published an article, "Popularization of Science: Revealing the Secrets of Power Battery Laser Welding," which comprehensively analyzes the application of power battery laser welding. In this issue, UW will focus on the seal pin welding of power batteries.

Difficulties in Seal Pin Welding

After encapsulating the cells into the battery shell, a liquid injection hole is usually left in the shell for electrolyte injection. After injecting the electrolyte, a rubber plug is inserted and carried to the seal pin welding station for final shell sealing. Therefore, seal pin welding is an important process to achieve complete isolation of the interior of the battery from the external environment.

It is understood that currently, the power battery mainly has two sealing methods: steel ball sealing, dispensing and curing, and sealing sheet laser welding. The amount and the dispensing shape are difficult to be consistent, resulting in differences in the consistency of the battery appearance. Therefore, most of the advanced battery manufacturers use seal pin laser welding.

During the process of liquid injection and transportation of the power battery, the electrolyte will remain in the cover holding tank and form crystals after standing for a long time, which will lead to inclusions or burst points when welding the seal pins and cause the power battery to be scrapped due to welding defects. Therefore, choosing a stable, efficient, and high-yield seal pin welding machine is particularly important.

Seal Pin Welding Machine Developed by UW Laser

The seal pin welding machine developed by UW Laser contains a series of fully automated processes such as battery injection hole positioning, injection hole cleaning, seal pin pre-welding, seal pin full welding, post-weld camera inspection, and seal pin feeding. With the energy negative feedback function of the self-developed laser, it can achieve a higher control accuracy and stronger electrolyte compatibility, and the final welding rate is ≥99.8%, which is the highest across the industry. At the same time, after evaluating a large number of actual cases, the highest efficiency across the industry can be achieved by equipping a UW-hybrid laser.

High Production Efficiency and Higher Yield Rate

Using the company's self-developed laser and control system, the final excellence rate is ≥99.8%;

A 3D camera is used for post-welding inspection, which can effectively detect welding defects such as pinholes, burst spots, broken welds, steps, etc., and no leakage, with an overkill rate of ≤1%;

Fully Automated Operation, Intelligent and Efficient Production

To achieve code scanning and recording of incoming materials, automatic loading and unloading, automatic battery clamping and benchmark positioning, automatic laser cleaning, automatic positioning and automatic assembly of seal pins, CCD welding and welding detection, automatic laser welding and dust removal, Automatic identification and rejection of defective materials, high efficiency, and good finished products.

The welding seam is exquisite, the penetration is stable, and there is no obvious splash during the welding process.

From laser welding and intelligent manufacturing, UW Laser has a number of power battery welding-related technology reserves and has deep technical accumulation in the fields of prismatic power batteries, pouch batteries, cylindrical power batteries, blade batteries, etc. The new energy equipment division and the new energy vehicle division specialize in developing and producing corresponding equipment and equipment and intelligent manufacturing solutions for the power battery industry and carrying out industrialization and market promotion.

In order to adapt to the explosive growth of the new energy market and to be closer to customers, UW Laser dedicates to setting up the "one center, three bases" pattern, which means taking Shenzhen headquarters as the center while building UW Jiangsu as the East China Base, UW Huizhou as the South China Base, UW Sichuan as the Southwest China Base, to provide customers with " localized" R&D, production, sales, and services. In addition, we continue to accelerate the process of internationalization and actively deploy overseas markets. So we are committed to becoming the world's leading mainstream supplier of laser welding equipment and intelligent manufacturing solutions!