Introduction

Fiber lasers have been widely used in the welding processes of various fields such as automotive parts, consumer electronics, shipbuilding, and power batteries, thanks to their remarkable advantages in improving processing efficiency, reducing energy consumption, extending equipment service life, and optimizing manufacturing processes.

However, when traditional fiber lasers are used for high-power welding, they are prone to causing serious splashing problems. The metal particles generated by splashing not only scratch the workpiece surface and contaminate the welding protective lenses but also increase the rework rate of products and cause potential production hazards such as damage to precision components. Moreover, the splashing of molten materials leads to raw material loss and creates porosity defects at the weld, reducing the stability and reliability of the weld structure.

As the new energy vehicle industry continues to raise the requirements for power battery welding processes, to address the challenge of spatter control and achieve efficient processing, the industry has been striving to break through the bottlenecks of traditional technologies. Through continuous innovation and R&D, the ring spot fiber laser has emerged.

This technology precisely regulates the beam energy distribution. While enhancing the stability of welding quality, it can effectively reduce the overall production cost and improve production efficiency.

1. Ring Spot Welding

Technical Principle

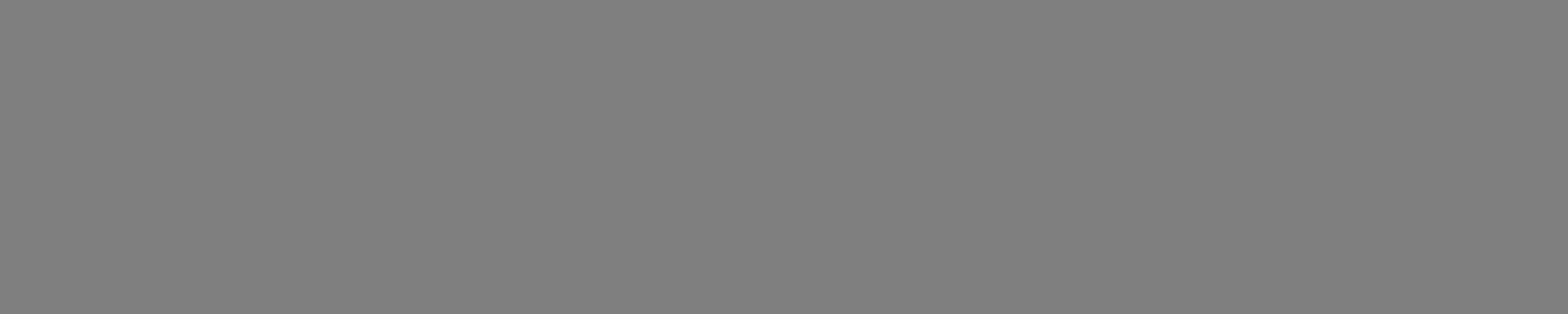

The ring spot laser provides two independently controlled coaxial laser beams through a single optical fiber. During the welding process, the central beam is used to form the weld seam, while the ring-shaped spot is used to stabilize the welding molten pool. This enables high-speed, spatter-free welding and almost eliminates defects such as cracks and pores.

Compared with ordinary fiber lasers, the ring spot laser transforms the single Gaussian distribution laser beam into a more complex ring-shaped beam composed of a ring and a central beam. Moreover, real-time and independent adjustment of the laser power and light-emitting time can be achieved for both spots, which brings greater flexibility and possibilities to laser welding.

2. UW Ring Spot Fiber Laser

Introduction

UW Laser has broken the foreign technological monopoly. Based on market demands, it has independently developed ring spot fiber lasers (with power ranging from 2000W to 10000W). These lasers combine the high brightness advantage of single-mode fiber laser with the spot distribution advantage of ring spot fiber laser.

They can meet the processing requirements of various non-ferrous metals such as red copper, brass, and aluminum. Suitable for applications like precision and high-speed welding of high-reflectivity materials, they can effectively suppress spatter, eliminate the need for post-welding treatment, effectively improve the welding quality and yield rate, and meet the needs of high-quality laser welding.

This series of lasers is equipped with UW's patented negative feedback power adjustment technology, which can extend the full-power lifespan of the lasers by over 20%. It can provide a maximum total output power of 6000W and flexibly adjust the output beam mode. It enables various power combinations of the central beam and the ring beam, such as 2kW+2kW, 4kW+2kW and below, and both the central power and the ring power can be adjusted arbitrarily.

It can also achieve special fiber outputs in multiple specifications, such as 34/102um, 50/150um, 50/600um, 100/300um, and 100/600um. It is mainly used in processes such as tab welding, top cover full welding, busbar welding, and side plate welding in the power battery industry.

Highlights

- High welding quality

There is no spatter during welding. The weld bead forms stably and has good consistency. The fluctuation of the penetration depth is smaller, which is beneficial to the process stability of batch welding products.

- Adjustable spot design

The power of the core and the ring core can be independently adjusted. By changing the power of the central area and the annular area, the energy distribution pattern of the output light spot can be altered. This can effectively reduce spark spatter, making the weld surface flatter and smoother, and enabling more process options.

- Long service life

By adopting UW's patented negative feedback power adjustment technology, the laser has a total power margin of more than 20%. It can meet the customers' long-term (over 5 years) full-load production needs, and the equipment has a longer service life.

- High photoelectric conversion efficiency

The photoelectric conversion efficiency can reach over 30%. It saves energy and electricity, and can effectively reduce the operating cost.

- Reduce customers' costs

The localization rate of the core components of the laser is 100%, and the self-production rate of the core components is 60%. Compared with foreign brands, the equipment cost can be reduced by more than 40%.

- Outstanding performance

It features a fully sealed frame and is equipped with an in-built air-conditioning system. It can ensure a constant temperature and humidity inside the chassis, enabling it to adapt to the harsh environment of industrial workshops with varying temperature, humidity, and dust.

3. Application Cases of the Ring Spot Fiber Laser

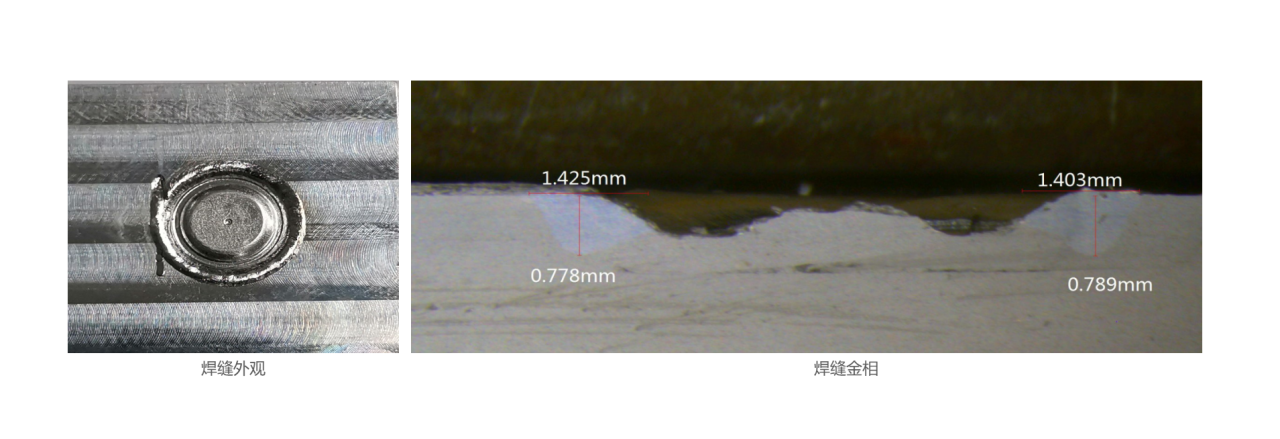

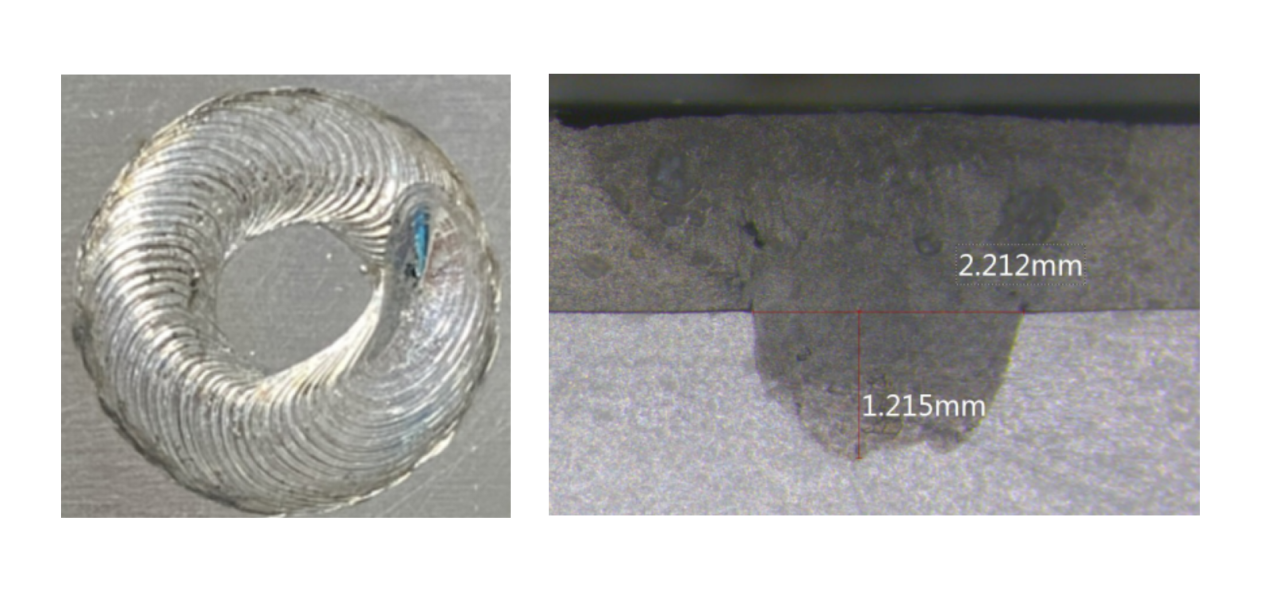

Battery Connector

Laser: UW-R6420U Material: Red copper

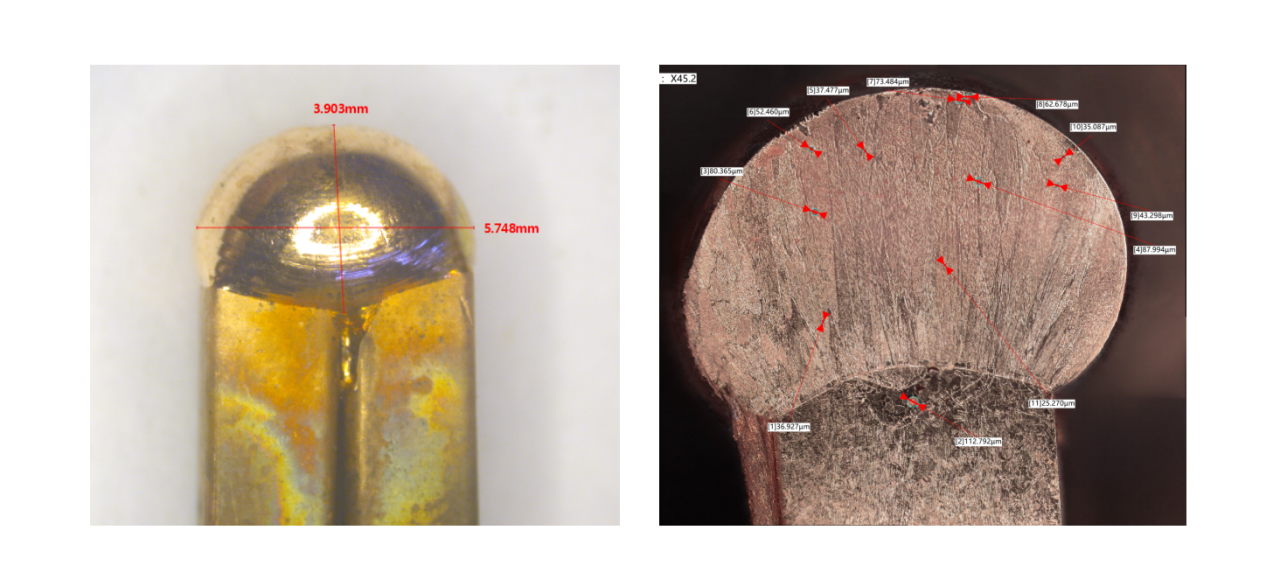

Battery Sealing Pin

Laser: UW-R6420U Material: Aluminum alloy

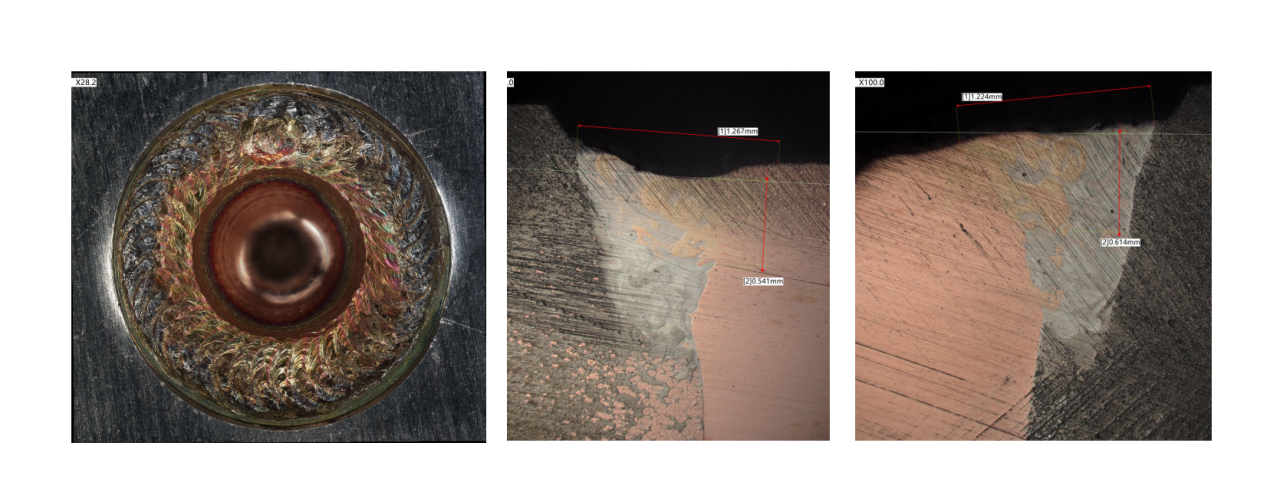

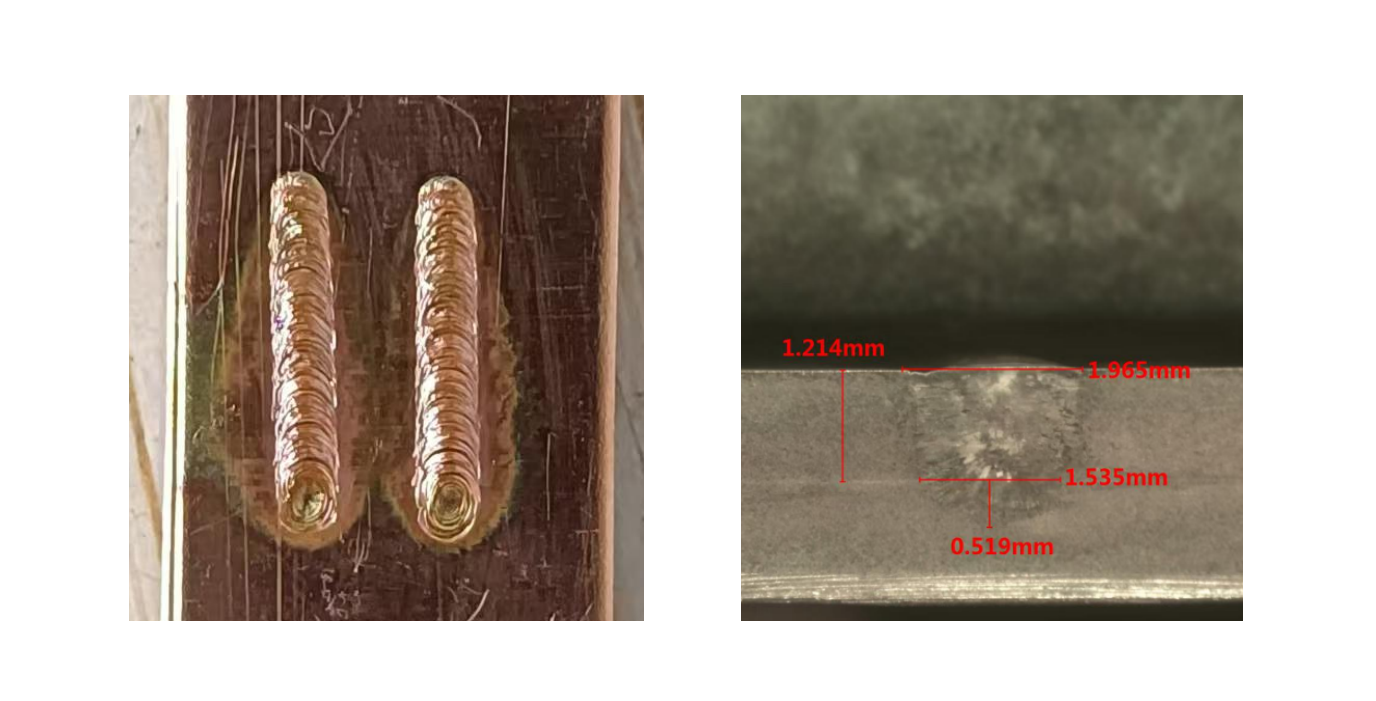

Copper-aluminum terminal post of the battery cell

Laser: UW-R4220U Material: Aluminum alloy+Red copper

Module busbar

Laser: UW-R6420U Material: Aluminum alloy

Flat Wire Motor Hair-PIN

Laser: UW-R6420U Material: Red copper

Various Copper Busbar Welding

Laser: UW-R6420U Material: Red copper

3D printing

Ring spot welding, relying on its special energy distribution and thermal management characteristics, demonstrates unique advantages in the field of 3D printing, especially in metal 3D printing. The UW ring spot fiber laser can significantly improve the quality, efficiency, and process flexibility of 3D printed parts by optimizing the energy distribution and thermal management, particularly in the fields of high-performance metal parts, complex structures, and multi-material printing.

As a national-level specialized, refined, distinctive and innovative enterprise in the field of precision laser welding, UW Laser, relying on its over 20 years’ experience in the field of laser welding, has established a full-spectrum technical matrix of lasers covering pulse lasers, semiconductor lasers, fiber lasers, blue lasers, hybrid welding lasers, etc. It can provide professional, high-quality and reliable laser solutions for intelligent manufacturing.