With the continuous acceleration of the green hydrogen industry, UW Laser has accurately assessed the industry's development trends and strategically laid out its presence in multiple hydrogen application markets. By focusing on high-power fuel cell systems as a key technology, UW Laser is continuously expanding into hydrogen energy storage equipment and providing comprehensive automated line solutions.

1. Graphite Bipolar Plate Dispensing and Sealing Line

Faced with different scenarios and complex dispensing process routes, the graphite bipolar plate dispensing and sealing line independently developed by UW Laser can respond flexibly through functions such as priority processing, route planning, adjustment of the starting dispensing process, and free canvas.

It integrates equipment such as the cathode plate loading machine, anode plate loading machine, adsorption platform dispensing machine, glue cutoff detection, pressing and curing, flipping machine, glue type inspection, glue strip curing, and leakage testing. It can significantly improve production efficiency and product quality. Meanwhile, it reduces manual intervention and cuts down production costs. It is especially suitable for industries that require high-precision and highly consistent dispensing processes, such as electronic manufacturing, automobile manufacturing, medical equipment manufacturing, etc. In addition, this production line can also be optionally equipped with different detection systems to meet various production requirements.

Highlights

Automated Production

All dispensing stations on this production line are equipped with needle alignment systems, eliminating the need for manual needle alignment and effectively reducing the issue of glue dispensing coordinate system confusion caused by needle changes.

High Precision

The production line is also fitted with multiple vision positioning modules and distance measurement modules, which are unaffected by tooling changes, ensuring the consistency of mass production.

Convenient Operation

The host computer software developed by UW Laser provides a straightforward and user-friendly interface, allowing users to access and save process recipes with a single click. It also supports importing CAD documents for setting and quickly adjusting dispensing paths.

Stable Operation

The host computer software comes with UW Laser's smooth motion trajectory algorithm. With intelligent dispensing control, it can ensure a smooth and stable dispensing process, guarantee the consistency of the glue pattern, thereby greatly improving the quality of dispensing.

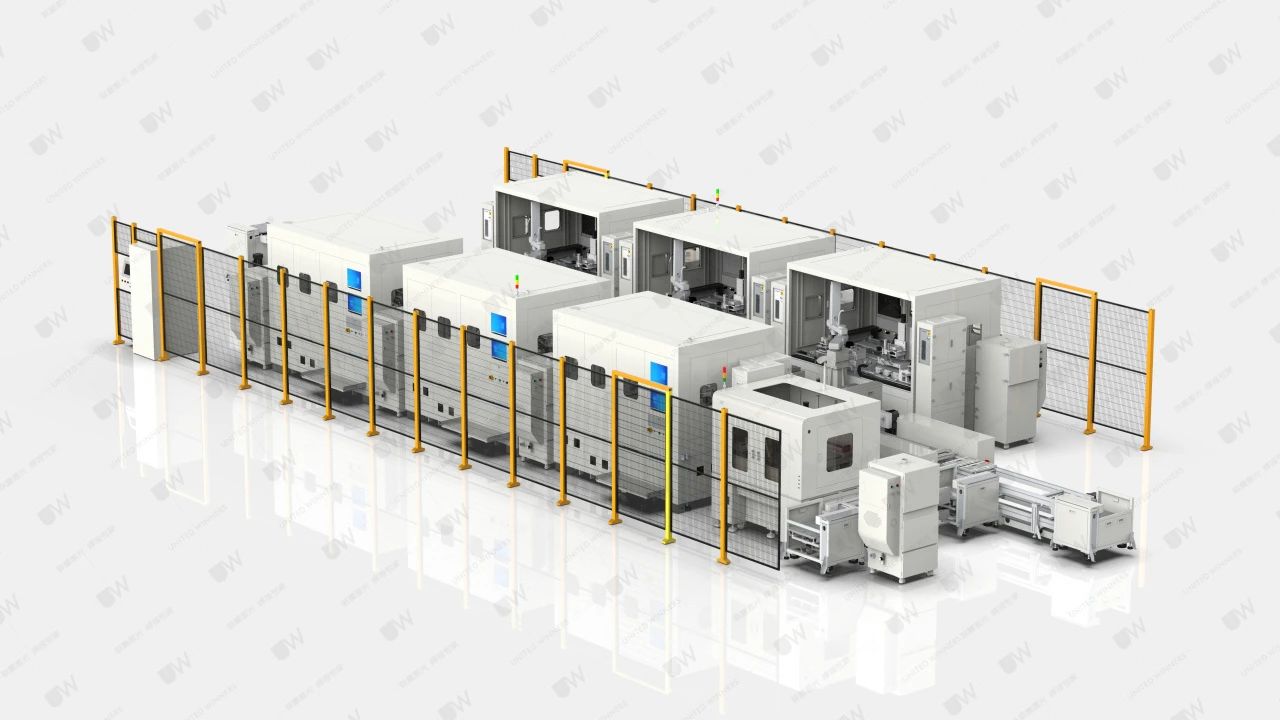

2. Metal Bipolar Plate Welding and Sealing Line

Bipolar plates are important components of fuel cells and a major part of the quality of the stack. They play an indispensable role in the operation of fuel cells and are required to possess characteristics such as good electrical conductivity, strong corrosion resistance, high mechanical strength, and light weight. The metal bipolar plate welding and sealing line independently developed by UW Laser has successfully applied laser welding technology to the processing of metal bipolar plates for hydrogen energy batteries, which can effectively improve the welding flatness and the yield of finished products.

The metal bipolar plate welding and sealing line can achieve flexible production and unmanned operation. It is mainly used for processes such as welding, airtight testing, appearance inspection, resistance measurement, thickness measurement, dimension measurement and marking. This production line consists of functional equipment including cathode/anode plate loading devices, bipolar plate welding equipment, bipolar plate airtight testing equipment, appearance inspection equipment, resistance measurement equipment, thickness and dimension measurement equipment and so on.

Highlights

Flexible production

This production line operates with robotic manipulators, featuring fully automatic loading and unloading. It has a high level of flexibility and a short changeover time.

Precise welding

The welding trajectory is imported into the program for automatic welding. It enables high-speed continuous welding with a fast welding speed and high precision. The fixture clamping design ensures the consistency of welding.

Efficient production

The equipment has a simplified structure and program, a low failure rate, low maintenance costs, and stable and reliable performance, which can achieve efficient production.

Real-time monitoring

Equipped with an industrial monitoring system and the function of information parameter traceability, it can conduct real-time monitoring of the welding process, which is helpful for quality control and problem tracking.

3. UW Bipolar Plate Dispensing Equipment

The bipolar plate dispensing equipment can be configured with fixtures, dispensing valves, heating, positioning, scanning, detection and other functions for the graphite bipolar plate or metal bipolar plate process section (openly select and use functions according to different product types).

Highlights

-The configured dispensing valve makes it possible to set up dispensing parameter formulations, and it is compatible with glues of various brands.

- The dispensing position status can be displayed in real time on the dispensing system.

- It enables rapid model change for fixtures of different products. The replacement of the dispensing needle can be activated with one click, without the need for re-teaching.

- The dispensing trajectory supports the automatic generation of dispensing points by importing CAD (DXF) files. The priority level of the trajectory can be freely set, and the glue plane can be automatically positioned.

4. UW Bipolar Plate Leakage Testing Equipment

This airtight equipment is mainly composed of a worktable, fixtures, pneumatic circuits, and a control system. The main frame of the equipment is made up of sheet metal and aluminum profiles, meeting the strength and quality requirements for industrial production, and it has a neat and elegant appearance.

Highlights

The equipment adopts modular design, with high flexibility. It comes with an embedded operating system, which enables convenient and flexible operation. This equipment features high detection accuracy and large memory capacity. It can simultaneously store 8,000 sets of test data and 32 sets of parameter settings on the instrument, meeting the requirements of most users.

5. UW Metal Bipolar Plate Welding Equipment

This equipment is composed of welding fixtures, PLC control systems, laser welding worktables, chillers, smoke purifiers, and so on.

Highlights

-This equipment adopts dual-station welding, which has high production efficiency. It features modular design, occupies a small area, and is convenient to operate. It can be used in conjunction with automated production lines.

-It is equipped with an industrial monitoring system, which enables real-time monitoring of the welding process.

-The highly reliable tooling clamping design ensures the welding consistency.