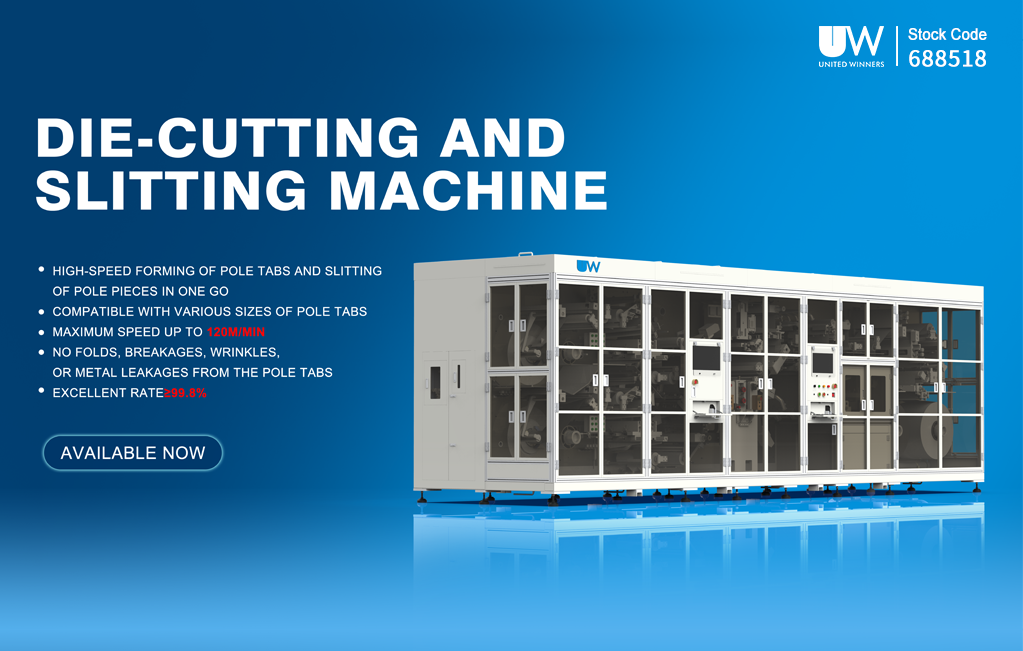

Integration of Die-Cutting and Slitting

Laser Cutting with Double Efficiency

Compatible with Various Size with Easy Changeover

High Yield Rate

As the power battery industry sprints into the TWh era, "extreme manufacturing" has become an effective path for leading power battery companies to enhance their competitiveness.

Battery cells are the smallest unit of a battery system. UW Laser has been deeply involved in the field of power battery laser applications for many years, and has profound technical accumulation and experience. It has therefore developed the fully automatic intelligent high-speed laser die-cutting and slitting machine based on the business development and market demand.

The die-cutting of pole tabs is to use a die-cutting machine to laser cut to form the conductive tabs for the battery cells, and the slitting is to cut the battery pole pieces by a cutter. The fully automatic intelligent high-speed laser die-cutting and slitting machine self-developed by UW Laser is equipped with an innovative self-developed galvanometer control software system for pole tab flying cutting, which can achieve high-speed cutting of multi-size and various types of pole tabs according to different customer needs. Its efficiency can reach 120m /min.

Through a high degree of innovation and integration, it breaks the traditional die-cutting machine + slitting machine cell production method, realizes the production function of laser cutting tabs + slitting with one device, and solves the high-speed forming of tabs and slitting of pole pieces at one time. It effectively reduces the customer's equipment, labor, site and other costs, solves the difficulty of changing the traditional hardware die-cutting and inefficiency in lithium battery manufacturing, and greatly improves the manufacturing efficiency and product yield of the die-cutting section in lithium battery manufacturing.

Technological innovation is the source of high-quality development of UW Laser, and it is also an important support for achieving greater development. From a big manufacturing country to a strong manufacturing country, the application of China's laser technology has become the key to many manufacturing industries to improve product quality, reduce costs, and ultimately improve competitiveness. In the future, facing the opportunities and challenges of diversified market competition, diversified customer needs, and accelerated product iterations, UW Laser will always adhere to customer needs as the orientation, continuously promote technological progress and product innovation, and empower the high-quality development of China's intelligent manufacturing!