When mentioning intelligent manufacturing, what is the first thing that comes to mind? Intelligent Equipment? Intelligent factory? Cloud, big data? Industrial Internet? Or is it a machine substitution? In fact, these are all scopes of intelligent manufacturing. The essence and the true meaning of intelligent manufacturing are using advanced technologies such as digitization, networking, and artificial intelligence to understand and control manufacturing systems' uncertainties and achieve higher goals.

As a high-end equipment manufacturing enterprise, UW Laser has been following the trend of intelligent manufacturing for several years to carry out forward-looking scientific research and technological innovation. Besides, the company continuously increases investment in enterprise informatization and intelligent construction, deepens industrial interconnection, creates automated intelligent factories, and takes practical action to help power battery enterprises achieve digital manufacturing and promote China's "intelligent" manufacturing!

MES: The Information Core of Intelligent Factory

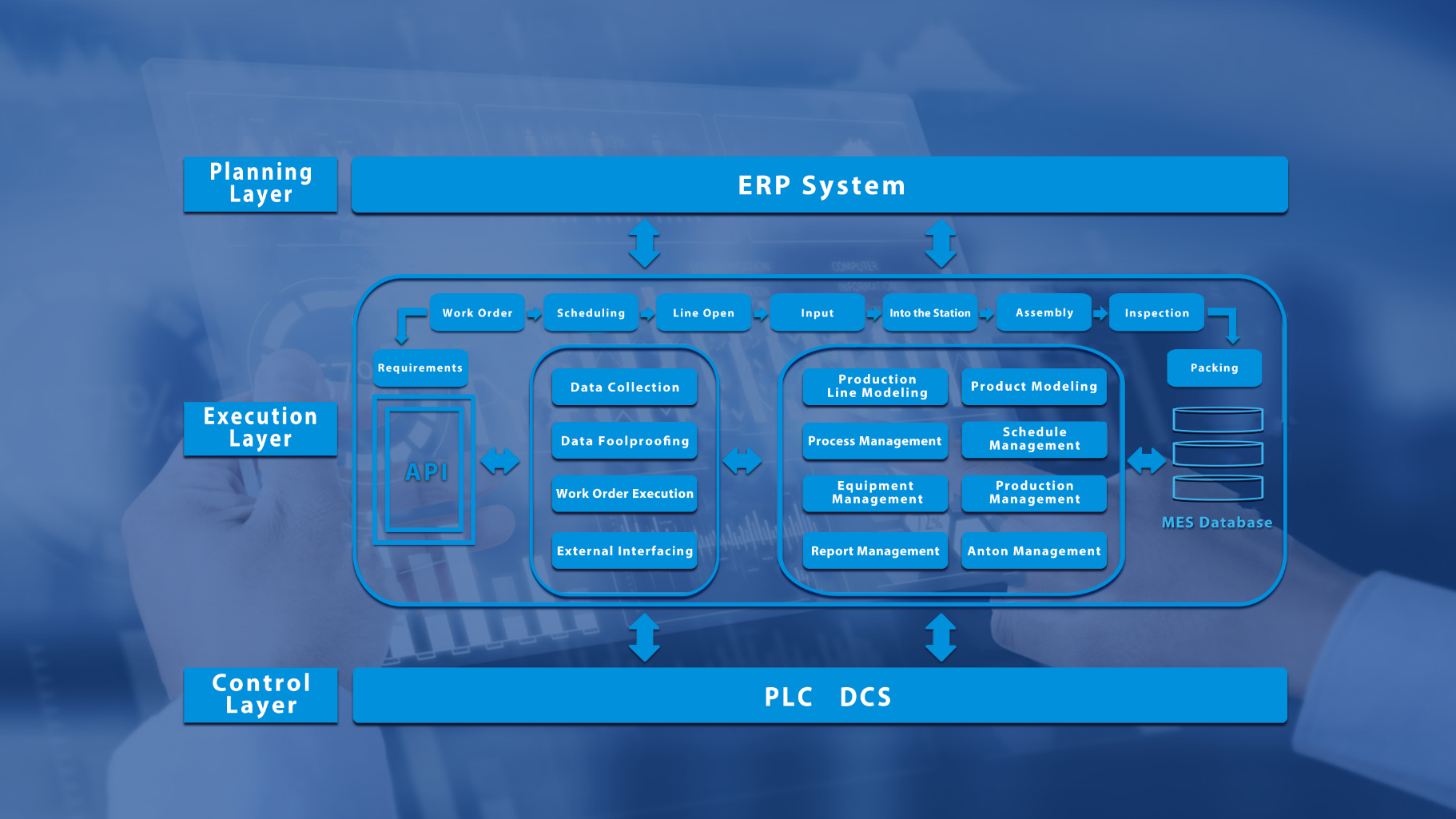

Intelligent factories are the core of intelligent manufacturing. Although enterprises at different stages of development and in different forms are promoting digital transformation and moving towards intelligent manufacturing on different paths, there is an indispensable common link in the process of constructing intelligent factories and leading to intelligent manufacturing, which is the Manufacturing Execution System (MES).

MES is the foundation of intelligent manufacturing construction. It covers the entire production process of intelligent manufacturing and is closely connected with various businesses of the enterprise. As a workshop-level integrated management system, MES collects information from the underlying automation control system and various types of equipment downward and takes over the production plan issued by ERP upward, effectively helping enterprises to improve the operational performance of factories in many aspects such as transparent production, agile production, production traceability, production quality improvement, timely alarming, and performance analysis.

Based on the experience in the lithium battery manufacturing industry, UW Laser has developed the UW Intelligent Manufacturing MES system to help users with the information technology to build a fast, flexible, real-time, and fine-tuned on-site operation command and control environment and effectively solve manufacturing problems. It can better control the production cost, improve the production efficiency, increase the production plan control ability, and then improve the comprehensive competitiveness of the enterprise.

Improve the Digital Operation and Management Capabilities

UW Laser has made multiple optimizations for the pain points in the production execution management of manufacturing enterprises, such as multiple orders and small batches, a product consisting of thousands of parts and accessories, more and more non-standard parts, and the difficulty of digital transfer between various positions, etc.

The UW Intelligent Manufacturing MES system organically combines enterprises from raw materials, storage management, production planning management, production process control, quality management, human resources management, equipment and tools management, finished goods storage/shipping management, on-site service, and after-sales management, etc. It realizes the quality traceability of the whole life cycle of products based on the transparency and standardization of workshop operations. It also realizes efficient access to all kinds of production equipment, objective production data, and intelligent enterprise operation management.

Data error-proofing, process route error-proofing, and assembly route error-proofing prevent products from skipping and missing stations.

To Build a complete production data file that supports forward traceability of the production process and reverse traceability of material information. So that it can facilitate "recall beforehand" and "responsibility afterward."

With the data integration of the underlying equipment control system, the data information such as equipment operation status, plan execution status, processing status, yield rate, efficiency and other data information obtained and transmitted by each collection point in real time can reflect the actual production situation in a timely and accurate manner.

Multi-dimensional analysis of the production situation and diversified statistical analysis methods provide a reference basis for product improvement.

Compatible with ERP, PLM, and other information systems, it realizes the exchange and sharing of basic data, product information, production plan, and production process data among multiple systems, eliminates the problem of information isolation among various systems, and realizes the digital flow of each process.

The production records, inspection records, and handover records in the production process are all managed electronically and systematically. For all kinds of information such as output, quality, logistics, environment, order production progress, and bottleneck problems in the production process, reports, and interactive Kanban can be automatically and timely generated to achieve paperless transmission of information.

To meet product diversification and individual needs, process routes and production tasks can be edited flexibly. The specific performance is that the process route can dynamically open some stations or close some stations according to the actual situation of the product to achieve flexible and efficient production.

The UW Intelligent Manufacturing MES realizes the coordinated and flexible application of different scenarios such as PC and mobile terminals through the local synchronous joint debugging of PC and mobile terminals, making management more accessible and more effective. In addition, based on the vast data pool accumulated over the years, The UW Manufacturing MES transforms production automation into digital intelligence through multi-party data integration and realizes the transition from the lithium battery MES to the intelligent factory.

The system automatically analyzes supply chain data and outputs reports for each link and pushes them to the person in charge of each link, making the reports more timely and accurate and facilitating enterprise managers to make plans and countermeasures in advance. It solves the pain points of enterprise production and operation and effectively improves enterprises' digital operation management capability.

Adapt to Individual Customization

MES is a combination of informatization and automation. Different companies and different product lines have different implementations of MES systems. Although there are already many intelligent manufacturing information systems, finding a suitable digital system for "personalized manufacturing" is still difficult, especially in non-standard industries.

In this regard, the UW Intelligent Manufacturing MES system provides users with customized services. The system can be combined according to different industries and customer needs. And It has good flexibility and customizability to meet customers' individual needs.。

The integrated digital economy and manufacturing industry development is a general trend. Digital technology and the digital economy are the opportunities for the world's technological revolution and industrial transformation and are the key areas of a new round of international competition. Make good use of the digital dividend, and let the digital economy improve the quality, efficiency, transformation, and upgrading of the manufacturing industry.

As a high-end equipment manufacturing enterprise, UW Laser is comprehensively accelerating the company's overall digital, networked and intelligent transformation. It continuously promotes the deep integration of digital intelligence technology and equipment manufacturing, accelerates the digital intelligence process through the industrial Internet, and gives full play to the enabling and leading role of digital technology in developing the equipment industry.